Convert your roller chain and large v-belt drives to Gates Poly Chain GT Carbon for a maintenance free alternative that extends drive life and saves you money and maintenance and boosts productivity.

MXT™ XTP

This new hydraulic solution is lighter, stronger, and more flexible!

Made with strong, high-performing reinforcement and high quality, abrasion-resistant rubber, MXT™ is a universally applicable premium product offering performance above industry standards. Its diversified application allows you to consolidate inventory while giving you exactly the hose you need, when you need it.

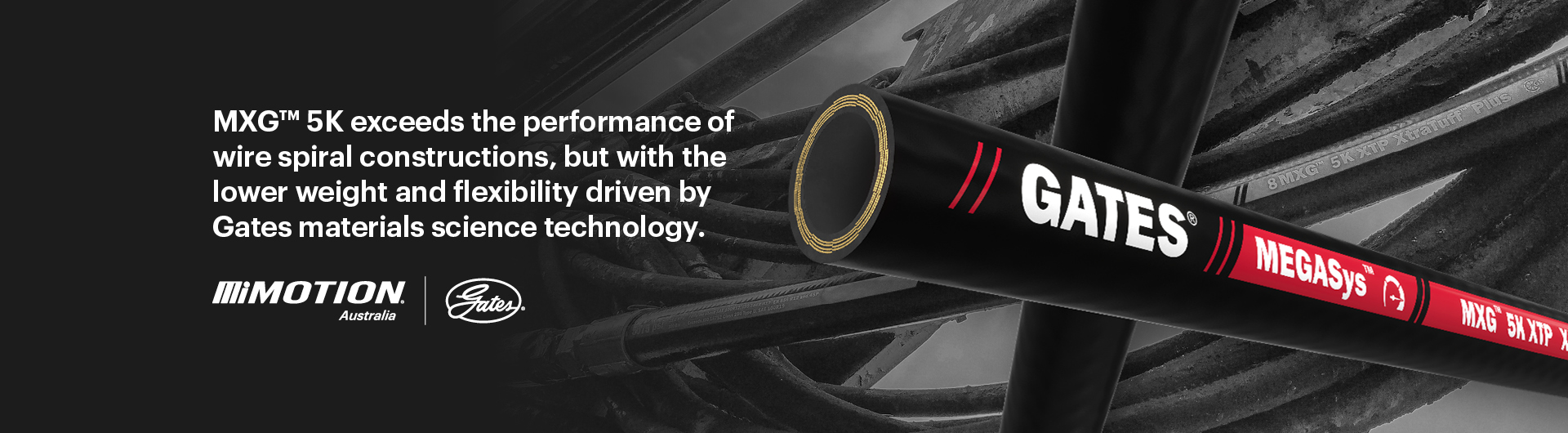

MegaSys™ MXG™ 5K Hydraulic Hose

Next-level performance that is engineered to maximise uptime and boost your productivity!

20% lighter, 25% more flexible, and 5% more compact than any comparable hydraulic hose on the market! The durable XtraTuff Plus cover delivers additional toughness with 25X abrasion resistance and 800+ hour ozone resistance.

Looking for the most cost effective and durable solution? Choose ‘Tension-free’ maintenance with Gates’ Predator V-Belts.

A more compact drive that provides greater power capacity at half the width and weight of a standard belt and at a third of the cost, with no change in shaft loads.

Innovation is what we do.

Quickly, easily, and accurately design industrial synchronous or V-belt drive systems that fit your specific design parameters, so you can determine every potential belt drive solution for your specific application without wasting any time or money. Our professional-grade design software allows you to print, email, or create PDFs of your design specifications from within the software, with automatic translations to service your global markets.

In addition to designing belt drives, Design Flex® Pro™ can be used to:

The Gates Belt Installation + Rotation Device (BIRD™) minimises finger and hand injuries due to hands getting caught in pinch points during routine installation and maintenance. While a drive is shut down and locked out, the BIRD™ safely facilitates a rotational inspection of a drive.

Prior to the launch of the BIRD™, in order to inspect or install a drive, personnel would pull on the belt or grab the edges of the pulley or sprocket to turn the drive. Regardless of the care taken, this procedure is inherently dangerous – a split second can lead to a hand or finger pulled into a pinch point.

The BIRD™ changes that. Ensure the safety of your staff and proper maintenance of your drives with the Gates BIRD™.

Gates Corporation is a leading manufacturer of application-specific fluid power and power transmission solutions. Gates is driven to push the boundaries of materials science to engineer products that continually exceed expectations.

Gates’ product range spans across: