Waste not, want not’ is an adage many are familiar with – it means that if a person uses resources wisely, there will always have enough. It is also one that David Caramia, the National Business Development Manager for Manufacturing at Motion, says applies to a sustainable industrial future.

“When we talk about the circular economy, it is about how keeping materials in use for as long as possible,” explains David. “That includes the parts in machines that are used to repair or recycle product. And this is where Motion can and does assist industrial companies in the waste and recycling sector – by ensuring they are keeping their machinery running optimally, minimising their own waste, and running more sustainably.”

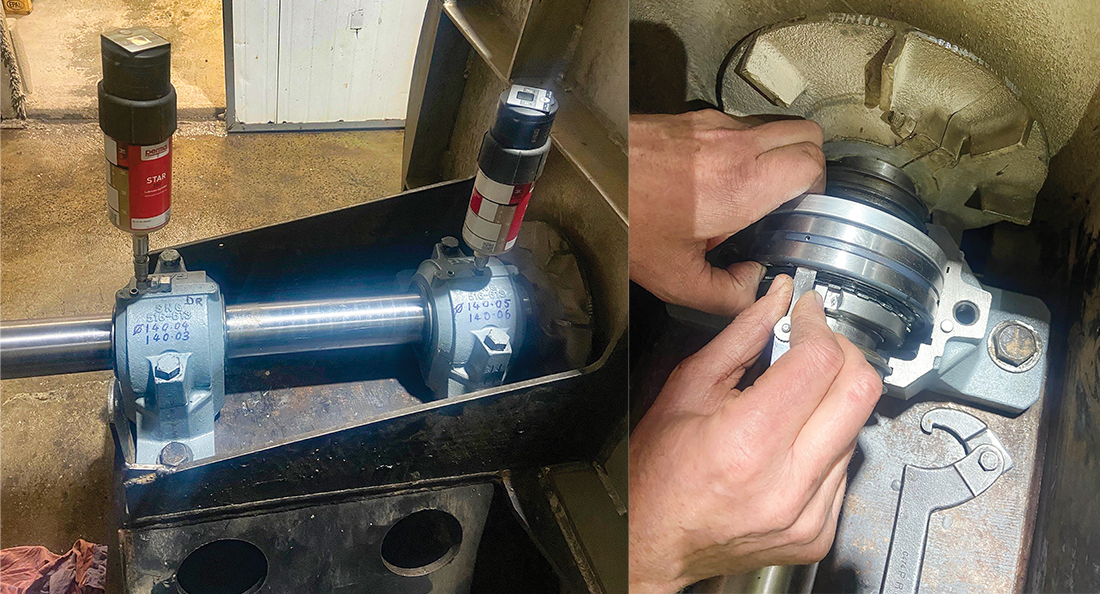

David – who has over 30 years of experience in the field of waste management – has been spearheading Motion’s efforts to provide comprehensive solutions to the challenges faced by the industry. From bearings, lubrication systems, and hydraulic hoses to engineering services and ongoing maintenance support, Motion is committed to providing customised solutions that cater to the specific needs of this industry.

David highlights there being various issues in this space, one is “the amount of waste generated by Australian households, and the lack of education about how to recycle this waste.”

According to the National Waste Report 2021, Australians generated an estimated 75.8 million tonnes of waste over the course of a year, with around 56% of this waste being recycled.1 David discusses there being room for improvement here and notes simple things that can be done at home, “like removing lids from bottles, which is often overlooked when people are recycling in the home.”

This is crucial for recycling as machines rely on air pressure to sort materials by weight and size. Bottles with lids on can potentially damage machinery and cause delays, and this can prevent adequate emptying and lead to contamination.

David also discusses the utilising of other recyclable materials such as tyres. According to a report by the Australian Department of Agriculture, Water and the Environment, around 56 million tyres reach the end of their life each year in Australia, with only around 10% of those being recycled domestically. 2

The remaining tyres are either exported overseas, stockpiled, illegally dumped, or sent to landfill. This poses significant environmental and health risks, as tyre stockpiles can catch fire and release toxic fumes, and landfilled tyres can leach harmful chemicals into the soil and groundwater.

Overall, these two examples show proper education of individuals on sustainable waste management practices is critical to promoting a more sustainable future. David highlights with the growing awareness of the importance of sustainable waste management practices, it is hoped that more individuals and businesses will adopt these practices and work towards a more circular economy.

While David acknowledges that there is little control over the actions of individual households, he highlights some of Motion’s capabilities to support the industry, including providing both collective and individual education.

The ability to have instant access to such knowledge through the Industry inMotion Magazines is a significant benefit for customers regardless of their industry. The magazines are an indispensable resource for customers of all types in the waste management and recycling industry, as well as other key industries.

Another Motion offering is ongoing monitoring and maintenance services provided by Motion Engineering, which can help in various ways.

“Plants often operate on a reactive basis, waiting for machines to break down before taking any action. This approach is not only inefficient and costly, but it is also detrimental to the environment. When equipment fails or malfunctions, it can lead to delays in waste processing and recycling, which can cause environmental pollution and health hazards,” David discusses.

He emphasises that by “adopting a proactive approach through ongoing monitoring and maintenance services provided by the Motion Engineering Team, plants can ensure that their equipment is running at optimal efficiency and safety, reducing the likelihood of breakdowns and the associated negative impacts on the environment.”

This type of educational support is a key feature of Motion’s offering and makes a significant difference in servicing the waste management and recycling industry.

Motion offers a diverse range of products, which includes lubrication systems, bearings, safety products, hydraulic and industrial hoses, material handling equipment, and more. David highlights the unique competitive edge that Motion possesses in the market.

“Our customers can rely on us for a complete package – something our competitors cannot match due to the breadth of knowledge and engineering skills we possess, as well as the range of products we offer.”

This unique combination of expertise and products enables Motion to provide customised solutions that cater to the specific needs of the waste management and recycling industries.

Motion’s leadership in the waste management and recycling industry is strong, but as discussed, individual actions also have a positive impact on the environment. David states “by collaborating with companies like Motion, the waste management and recycling industry can make great progress towards a more sustainable future.”

References

- https://minister.dcceew.gov.au/plibersek/media-releases/australias-latest-waste-figures-new-report

- https://www.tyrestewardship.org.au/news/turning-trash-into-treasure-how-australias-tyre-stewardship-initiative-must-pave-the-way-for-a-circular-economy/