Speed and efficiency are the most important parameters for any metal worker when selecting grinding wheels. But cutting metals faster and cleaner does not need to be more expensive. The new 3M™ Silver grinding wheels represent a class of cutting wheels that are both tough on metal and cost-effective.

As Nathan Bamford, Senior Application Engineer at 3M explains, the 3M Silver range use similar precision shaped grain technology as found in the premium 3M™ Cubitron™ II products to deliver speed and long life, but at a value price.

“The 3M Silver range outperform conventional aluminium oxide wheels but sit just below our premium Cubitron II range. In our Right Choice Catalogue, we use a star rating, with the Cubitron II range having 5 stars and the Silver range given a 4-star rating.”

The Silver range by 3M includes both Depressed Centre Rigid Grinding Wheels and Cut-Off Wheels. With both of those models, Nathan says the secret to the high performance lies in the precision shaped grain technology.

The service life in grinding wheels depends on many factors, but Nathan notes that abrasive products with precision shaped grain technology generally have significantly improved life compared to conventional discs.

“When cutting steel and stainless steel tubing assemblies using 3M Silver Cut-Off Wheels, our customer reported 50% less wear compared to their standard aluminium oxide wheel. For cutting structural metal sheet and plate, the 3M Silver Cut-off Wheels demonstrated 40% less wear than this customer’s usual AZ wheel.”

To further explain the technology used by 3M, Nathan draws a comparison between grinding wheels using conventional grains and those using precision-shaped grains.

“In the conventional abrasive discs, the grains are randomly distributed in the coating covering an abrasive backing. This irregular cutting surface results in a ‘ploughing’ effect as it cuts through the material. This ploughing causes heat to build up in the workpiece and the abrasive, which dulls the grain and eventually reduces the wheel’s service life,” says Nathan.

“The precision-shaped grains, on the other hand, use the 3M microreplication technology to form sharp peaks that easily ‘slice’ through metal. This action prevents heat from building up in the workpiece and therefore prevent heat-related stress cracks and discolouration. Also, because the abrasive itself stays cooler and sharper, it lasts longer than conventional grain,”

he adds.

Selecting the right grinding wheel for each application can be complicated. They are available in a variety of sizes, shapes and grits. Nathan’s recommendation is to refer to 3M’s selection chart or to consult 3M abrasive specialists to recommend the best product for each application.

BSC, a key supplier of industrial abrasives and other industrial components in Australia, also actively supports customers with selection for their abrasive needs. BSC Product Manager Michael Rowe says BSC specialists are always available for assistance when needed.

“Our team can facilitate to set up trainings or demonstration sessions for metal fabricators who want to assess the cost benefits of 3M grinding wheels. With our many years of experience working with almost every industry in Australia, we understand the customers’ grinding needs and we can recommend just the right product for their needs.”

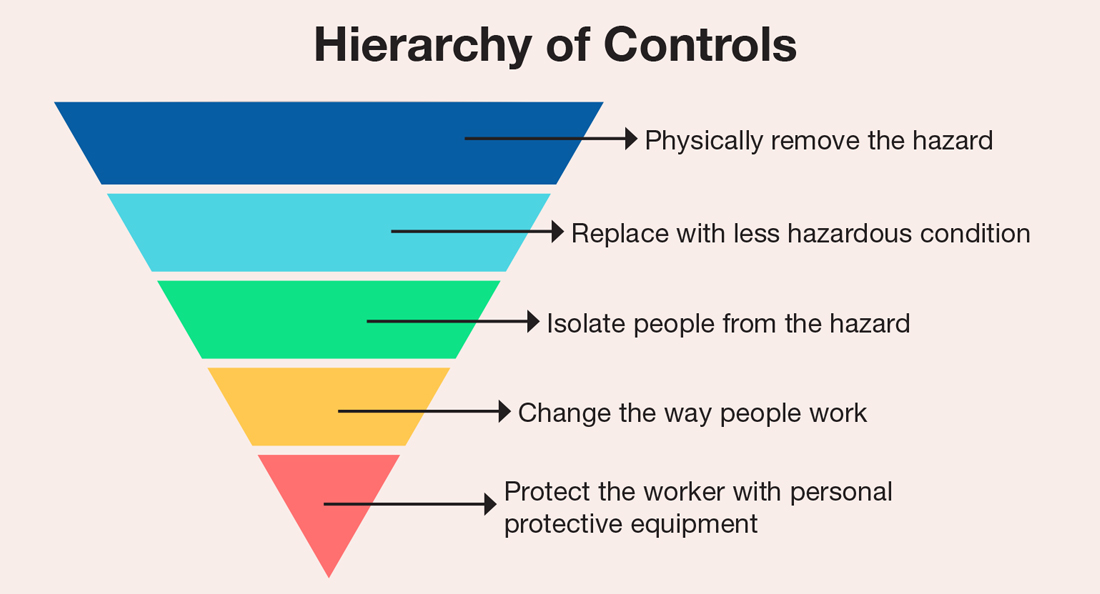

For maximum safety while grinding, follow these steps:

1. Elimination: Modify the task or workplace so that the hazard is no longer present.

2. Substitution: Replace the hazardous material, equipment or activity with a less hazardous one.

3. Engineering controls: Modify the design or specification of tools or equipment to isolate or reduce the exposure to the hazard.

4. Administrative controls: Introduce working practices and procedures that remove or lessen the risk.

5. Personal Protection Equipment (PPE): Protect the worker with suitable PPE.