As the foundation of all industrial applications, the business of bearings is one of continuous improvement. From the design of components such as the roller and cage features, to surface finishing, to sizing; the intricacies of a bearing are many

and varied.

Schaeffler Australia is a company that focusses on honing the design and technology for each line of products they supply. The drive to improve their products and having ownership over engineering decisions is what inspired the launch of X-life series, with the bearing series recently passing the ten-year mark.

As Engineering and Quality Manager for Schaeffler Australia, it is Andreas Pieper’s job to promote the X-life series in Australia. Andreas recently highlighted the history of X-life developments in a training presentation he delivered to suppliers across Australia, including the team at CBC, getting them up to speed on the latest technology and developments. CBC branches across Australia have been distributing X-life products since their inception.

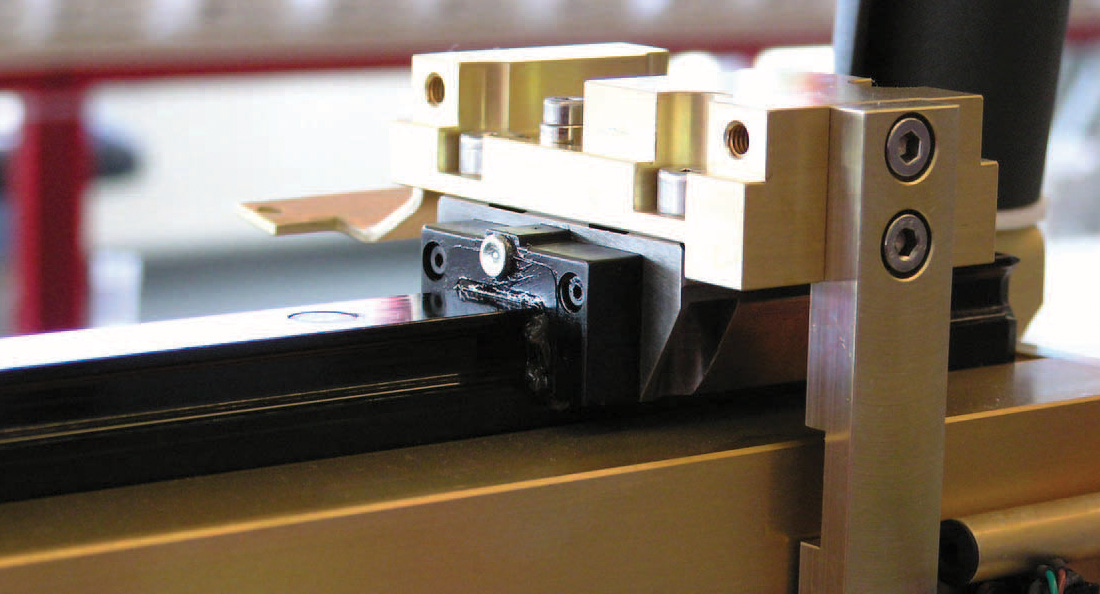

“For X-life, we do a lot of testing to verify and quantify what kind of improvements are generated by our changes over a period of time. We introduce production technology to the different factories. This goes along with investment planning, commissioning machinery, and training the teams,” Andreas explains.

Presently, nearly 60% of Schaeffler products are classified as X-life – meaning they have been improved and enhanced in terms of both design and manufacturing. As Andreas adds, there are two more elements Schaeffler is currently working on.

“These include expanding the spherical roller bearing X-life quality to the 233 series and introducing X-life into large sized spherical roller bearings,” says Andreas.

There are six major bearing types in X-life products: radial spherical roller bearings, axial spherical roller bearings, tapered roller bearings, ball bearings, spherical plain bearings, and cylindrical roller bearings. Depending on the series, there are certain characteristics that have been applied to improve their overall performance in an application. A higher dynamic load rating means that an X-life bearing running under the same application as its competitors will operate for a longer nominal life because it can take the given load better and has more capacity.

“The customer pays the same price for a bearing that can do more. In a greater context, the cost of a bearing is only a fraction of the cost of the activity to replace bearings. It requires a technician to get the gearbox out of the machine, dismantle the gearbox, replace the bearing, put the gearbox back together, transport it back to the mine site. This costs much more than the bearing itself. In the course of ten years, if a customer only had to do this two times, rather than three times, there is a huge cost saving,” says Andreas.

Improved surface features of the raceways and roller elements on the bearings, means lower friction. Andreas explains, “This makes the bearing generate less heat from friction, which means lubricants will last longer. Lubricants age more quickly with heat. Less friction also means you need less power to rotate the machine, which means reduced energy consumption.”

Another energy saving characteristic is an increase in product robustness. X-life bearings are more resilient in challenging operating conditions such as high speeds, vibration, centrifugal forces, and shock loads. Andreas provides an example. “Conveyor belts can be kilometers long and they all run on conveyor rollers which are supported by two bearings. If each bearing has less friction, and you have ten thousand bearings in a system, that is a lot of reduction in emissions.”

CBC continues to work closely with Schaeffler to broaden their supply for the X-life series, facilitating expertise to achieve a new standard of quality bearings for industrial applications.