The rigorous conditions of industrial operations cause heavy vibrations and structural borne noise from the shock of heavy loads.

The impact that this can have on valuable operational equipment, particularly mobile installations, can range from threatening the structural equipment– resulting in incidental equipment failures– to health and safety risks.

The best method to manage and control the risk of vibrations on heavy industrial and mobile equipment is to apply isolation technology. This uses passive isolation to contain the structural vibrations and dampen their effects.

Since 1932, Mackay Consolidated Industries has been manufacturing and supplying premium quality vibration isolators to the Australian industry. From humble beginnings as a small but efficient supplier of OEM approved automotive parts, it has grown into a success story as the largest and most trusted rubber engineering and manufacturing company in Australia.

The business has been singularly successful in the specialised field of noise and vibration technology. Their expertise in this area has led them to serve the automotive, defence, transport, rail, marine, mining, construction, and industrial markets at home, and around the world.

Mackay’s in-house engineering team in Australia utilises state-of-the-art technology and systems, as well as a NATA accredited laboratory for testing and qualifying. For applications requiring special design or isolation characteristics, they work closely with customers to perform finite element analysis, developing custom 3D modelled isolator designs for manufacture.

As every application requires different engineering, Mackay Consolidated Industries has developed an extensive, diverse, and adaptable range of flexible isolator solutions that can be applied to a wide variety of industrial applications.

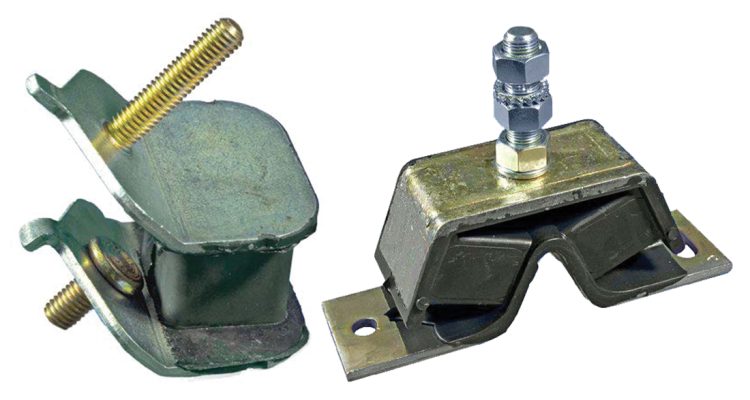

For those that require high levels of isolation and have low-load engines, such as portable generator sets, compressors, and motor pumps, Mackay has developed their Single V-Shaped Flexible Isolator.

Consisting of two symmetrically tilted metal parts with a screw on each side, this relatively simple solution has powerful vibration isolation capabilities. The V-shaped mounts make it possible for the more elastic installations to achieve a much lower frequency isolation.

For example, on a single-cylinder diesel or petrol engine running at 3000 rpm, the Isolators can attenuate more than 90 per cent of transmitted vibrations. Stability of the isolators can be enhanced when two are installed, symmetrically opposed.

Similarly, Mackay’s V-Shaped Marine Flexible Isolator solution has the same construction to provide major deflection at low loads. This means that the natural frequency is ideal for engines that would normally work ticking over, such as small vehicles or machines, small and medium sized generator sets, or marine engines.

The Marine arrangement is comprised of two metal parts which permit installation by means of a screw at the top, and two holes for securing it to the chassis.

Mackay distributes the V-Mount Flexible Isolators through Motion Australia’s businesses including CBC, BSC, and WebsterBSC.

V-Shaped Isolators – Key Features and Benefits

• Ideal for portable generator sets, compressors, and motor pumps

• Two different length screws which facilitate the assembly of the engine to the chassis

• Two “anti-turn” tabs which stop the mount from turning when strong tightening torque is applied even with pneumatic tools

• Available in two different stiffnesses to adapt to different load ranges

• Certified to ISO 9001 and AS/NZS ISO14001:2004 standards

V-Shaped Isolators for Marine – Key Features and Benefits

• Ideal for small vehicles or machines, small and medium sized generator sets or marine engines

• Available with three different stiffnesses per axis X,Y,Z to be able to adjust the modes of the suspended unit to obtain an optimal isolation

• Works with the elastomer in shear and compression

• Comprised of two metal parts which permit installation by means of a screw at the top and two holes for securing it to the chassis

• Certified to ISO 9001 and AS/NZS ISO14001:2004 standards

For more information on Mackay products and their range of Flexible Vibration Isolators, visit your local Motion Australia branch today.