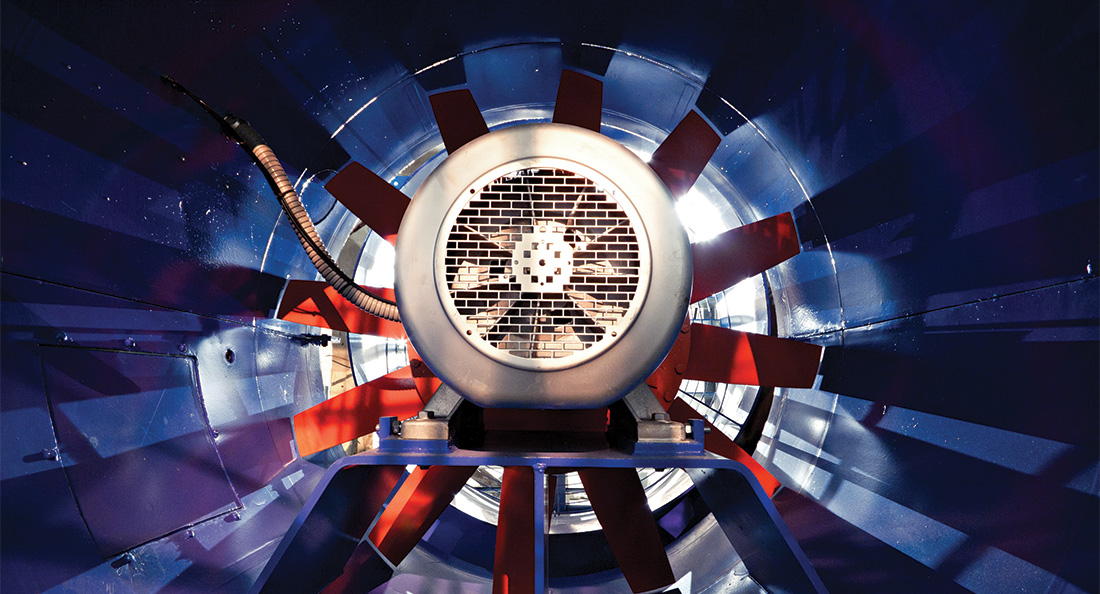

Designed to take radial and axial loads at high speeds, Angular Contact Ball Bearings are often essential to the performance of industrial pumping applications. Which is why having quality bearings in stock is important.

“I encourage customers to increase their inventory and holding of critical spares, such as these type of ball bearings, which are widely used for pump repair,” says Anthony O’Keefe, Regional Business Manager for Motion Australia. “With parts supply being an ongoing issue, it’s important to plan ahead.”

According to Anthony, the NSK Angular Contact Ball Bearings are high-quality bearings suited to pumping applications.

“NSK is a reputable brand, and their bearings are widely accepted as being high quality,” he says. “In particular, the Angular Contact Ball Bearings are renowned for their suitability to industrial pumps.”

Nitin Verma, Industrial Business Development Manager at NSK, explains that the NSK HPS series of high-capacity angular contact ball bearings are designed to operate under high loads and at high speeds.

“They’re highly reliable for critical machinery and equipment such as when pumps or fans are the predominant application,” he says. “NSK’s HPS (High Performance Standard) Angular Contact Ball Bearings offers high machine performance, avoid unplanned downtime, and promote total cost efficiency.”

HPS Angular Contact Ball Bearing’s internal design is different to standard bearings offering bigger balls thus increased dynamic load ratings to cater high load conditions.

“The ball size in the HPS Angular Contact Bearings is bigger than the standard and provides customers with the advantage of being able to use a smaller size bearing that has a higher capacity rating,” says Nitin. “In conventional applications this means the bearing will have a longer operating life and less maintenance, but it also facilitates downsizing the design envelope in certain applications.”

Another key benefit of the NSK HPS series is that they have different cage options to choose from. These include machined brass, polyamide resin, pressed steel cages, and L-PPS resin cages. The machined brass is a heavy-duty design suited to chemical, pulp, paper, and petroleum applications. Polyamide resin cage is appropriate to standard duty and high-speed applications while the pressed steel cage is better for medium duty. The L-PPS resin cage is specifically designed for screw compressor applications to handle corrosive liquids and gases.

“It’s important to select the right cage for the application as this will impact the rolling bearing performance,” advises Nitin. “Additionally, these bearings are offered with different clearance and preload options.”

The NSK HPS are available in dimensional series 72 and 73 for bore diameters from 12 to 120mm. They have a running accuracy to ISO tolerance class 5 and dimensional accuracy to ISO tolerance class 6.

“These bearing can be offered in higher precision like ISO Class 4 and Class 3 and can in different configurations like back to back, face to face, tandem etc – this brings benefits such as being able to run at higher speeds with higher rigidity,” says Nitin. “The universal and interchangeable matching also ensures highly accurate positioning.”

To ensure bearing features are correctly matched to critical equipment such as industrial pumps, Anthony recommends customers consult with their local Motion Australia branch.

“We work with partner suppliers such as NSK to ensure that selected bearings are suited to their application and can also advise customers on availability of stock and planning for future supply.”

Benefits of the NSK HPS Series

• Increased load capacity derived from optimised internal design

• Bearing fatigue life increased as much as 90%

• Higher limiting speeds, increased by 15-20%

• Highly accurate axial positioning achieved with high precision tolerances and standard universal arrangement

• Reduced heat generation, vibration, and noise