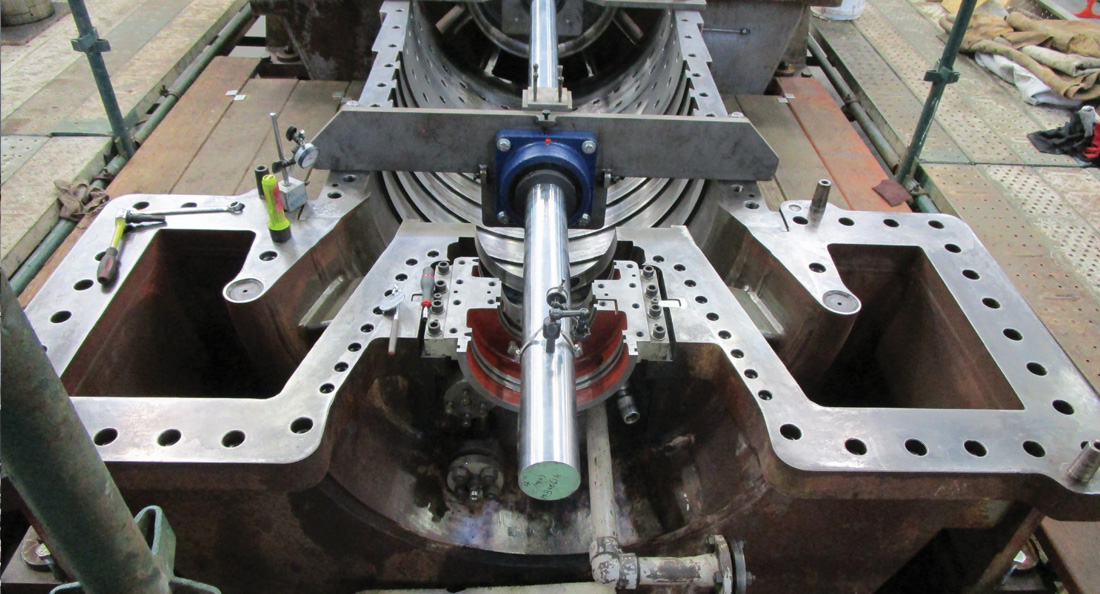

When Acora, a New South Wales business specialising in design, sale and installation of sawmill equipment, sought the expertise of CBC’s Wollongong branch to find suitable couplings for their heavy-duty machinery, the CBC sales specialist, Jose Costa, recommended the Lovejoy Quick-Flex® couplings by Timken.

Rex Rogers, who oversees engineering services and workshop management at Acora, says the couplings’ high torque ratings and reliability under repeated loads made them a perfect fit for Acora’s softwood and hardwood processing equipment.

“Our design calculations specify certain torque ratings that the Quick-Flex® couplings meet and even exceed. Some of our customers specifically ask for these couplings to be used in their machines; which is why we have used them in a number of our projects,” says Rex.

“For example, we use the Lovejoy Quick-Flex® couplings by Timken in primary and secondary log decks that are used to singulate large quantities of wood logs before they are driven through a de-barker. We also use them in our scanner conveyors, log haul machine and even in the kicker mechanism that kicks the logs,” he adds.

The reliability of Timken’s products was another key factor for Rex when it came to choosing the Quick-Flex® couplings, he says.

“It’s important that the couplings we use can withstand repetitive loading. The machines we design often run for double shifts. That’s 16 hours of heavy work per day. Quick-Flex® couplings have shown good performance under such condition,” he says.

“Also, using Timken products is a personal preference for me, because in my experience, I’ve found them to be very reliable. If we have a project that involves re-building a de-barker or any other machine, then we use Timken parts throughout to add more reliability to the equipment,” Rex adds.

Based in Eden in the South Coast region of New South Wales, Acora – formerly named Reneco Engineering – has been operating since 1967, making logging equipment for the softwood and the hardwood timber industry in Australia and New Zealand.

Rex says the close relationship with the CBC branch in Wollongong is something he values greatly.

“Over the past three to four years that we’ve worked with CBC, we have never had any issues regarding stock availability. The CBC team in Wollongong is very helpful. Jose Costa, whom I speak to regularly, has been really helpful whenever we had any queries. That’s why we continue to work together,” he says.

Jose says he’s happy to be working with Rex and the team at Acora, supplying them with spare parts and couplings when they need them.

“Unfortunately I have not been able to visit Acora’s workshop yet since they are located five hours away in Eden. But we’ve been regularly in touch via email and phone and maintain a close working relationship that continues to grow,” says Jose.

Brian Crouch is another CBC specialist who has been involved in the bearing and power transmission industry for over 43 years. Of those, he has spent the past 37 years with CBC Geelong as an accounts manager – a job that he says he cherishes for the opportunity to work closely with customers to solve their problems.

Brian says he recommends using Lovejoy Quick-Flex® couplings by Timken in high-torque and high-speed applications, to provide a longer service life to the equipment – be it a gear box, drive, or any other rotating element.

“Quick-Flex® couplings offer high service life under harsh work conditions or where high peak torques are expected. This is because of the solid and split cover assembly of the couplings,” he explains.

Another benefit of using Quick-Flex® couplings, Brian says, is that they can replace at least six other types of couplings; thus, simplifying inventory and stock management at the workshop.

“With so many different types of couplings available, it’s a lot easier for workshops to stock fewer types of couplings in their inventory. Quick-Flex® couplings can safely replace existing jaw couplings, grid couplings, gear couplings, chain couplings, disc couplings and tyre couplings. So you can have one coupling to do all of those six couplings’ jobs. Imagine the time-saving and cost-savings that this brings,” he says.

Higher efficiencies can also be achieved when replacing the coupling inserts, according to Brian.

“When you use Quick-Flex® couplings, you don’t need to disassemble the drive equipment to remove the hubs. The split cover design means you can replace the insert quickly and easily without removing the hubs, which creates more productivity and reduces downtime,” he explains.

“Because there’s no metal-on-metal contact with Quick-Flex® couplings, they also do not need any lubrication and the metal components remain intact. You can use these couplings in extreme heat and also high torque applications with a lot more efficiency than the other coupling types that I mentioned before.”

Brian says any sale by the CBC team is backed with engineering services and support to provide the right information to the customer.

“Lovejoy Quick-Flex® couplings by Timken can stand up to two degrees of misalignment, but it’s still important that they are set up correctly to perform effectively. We always specify the technical information, particularly when we go to do a new installation to ensure that the coupling is set up correctly to perform to its optimum performance. This comes back to that engineering support that we offer with every sale that we make,” he concludes.