Electric motors are the biggest electricity consumers across all industries. In heavy industries such as mining and refineries, where they are used to drive most of the minor processes, electric motors represent over 80% of electricity use.1 Across other major industries, they are responsible for around 70% of total electricity consumed.2

The International Electrotechnical Commission (IEC) classifies electric motors into four categories – IE1, IE2, IE3, and IE4 – based on their efficiency level. The efficiency range of each series is better than the previous series, with the IE1 motors fitting in the standard efficiency range, the IE2 motors in the high-efficiency range, the IE3 motors in the premium efficiency range and the IE4 motors in the super premium efficiency range.

In recent years and in view of the rising need to reduce greenhouse effect, the market for higher efficiency motors has been growing. According to a research report by Markets and Markets3, the energy-efficient motor market is projected to reach $US41.6 billion by 2023 from $US30.3 billion in 2018.

Industry expert Koorosh Faraji argues that the financial gain from a small upgrade in electric motor efficiency level can be significant when seen in the context of total cost of ownership.

“The electric motor’s purchase price represents only about 2% of its total cost of ownership,” says Faraji, who is Acting Regional Manager for TECO Australia Electric Motor Division – South. “More than 90% of an electrical motor’s total life cost is related to energy use. This is why a small improvement in efficiency can go a long way.”

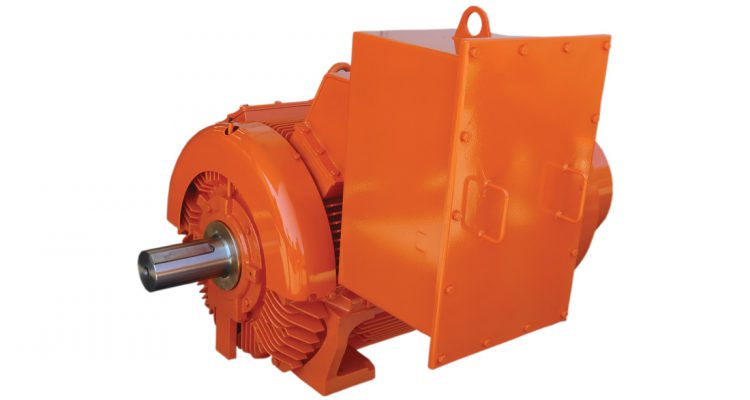

TECO, as a leading manufacturer and supplier of electrical motors in Australia and worldwide, offers electric motors in the high-efficiency range to suit different industrial applications.

Faraji says the high-efficiency TECO MAXe3 motors are specifically aimed at the mining industrial market as they can tolerate ambient temperatures in excess of 60˚C and are also designed with heavy-duty bearings as part of the motors’ mining specifications.

“The TECO MAXe3 motors can provide the best payback periods and the lowest cost of ownership. They are designed to minimise transmission losses in the supply cables and transformers to ensure higher power performance with lower energy consumption.”

The TECO motor was recently deployed by a major Australian recycling company as they sought to urgently replace a worn-out conveyor motor for their crushing mills.

Brad Hudson, Key Account Manager at CBC Australia, was the one who proposed the TECO motor as a suitable fit for the mill’s conveyor. As a key supplier of industrial parts and services to the recycling company, CBC had been checking on their equipment’s performance to help the company avoid unexpected downtimes.

“The conveyor carries the crushed materials to a cracker mill where they are crushed down further for use in different applications. This was a very critical motor because if it went down, the whole mill would be shut down,” says Brad.

With TECO’s assistance, CBC was able to deliver a replacement motor within minimal time to help the plant avoid a critical shutdown.

“The old motor had been fitted to a different shaft size than the TECO motor was originally designed for. Also, the frame height needed to be adjusted by about 40 centimetres to fit a new motor in. Working together, CBC and TECO were able to make the necessary adjustments to deliver the motor in time for the urgent replacement.”

Brad says the client has since experienced a significant gain in efficiency after changing a standard efficiency motor to an IE2 TECO motor.

“They are very pleased with the fact that we could hep them out quickly, and that too with a motor that offered a higher efficiency rating than their old motor. The customer has since placed more orders for electric motors for their plant, which will help them further reduce on electricity costs.”

1. https://www.ipieca.org/

2. Science Direct, “A study on electric energy consumption of manufacturing companies in the German industry with the focus on electric drives.”

3. https://www.marketsandmarkets.com/Market-Reports/energy-efficient-motor-163.html