Sharp tools such as scissors, knives and appliances used for cutting and shredding are a common source of injury, with many resulting in hospital visits on a daily basis. Almost one third of all injuries from 15–24-year-olds are cut from knives, which shows the less experienced user is at increased risk.1,2

Knife related LTI’s (Lost Time Injuries) often happen when knives slip during cutting or trimming. In most cases the blade encounters the worker’s other hand, causing a laceration to the hand and/or fingers. Injuries can also occur to other parts of the body, including the hand or arm operating the knife.

Knives can be useful tools in the workplace when the right knife is chosen, like a safety knife or shrink wrap slitter, and in the hands of a trained worker they can be used safely.

As knives in particular are considered an “all-purpose tool,” this often results in injuries that can take place in various settings such as the home, but also the workplace. When injuries occur at work, employees sometimes have to take time off while they recover, negatively impacting businesses.

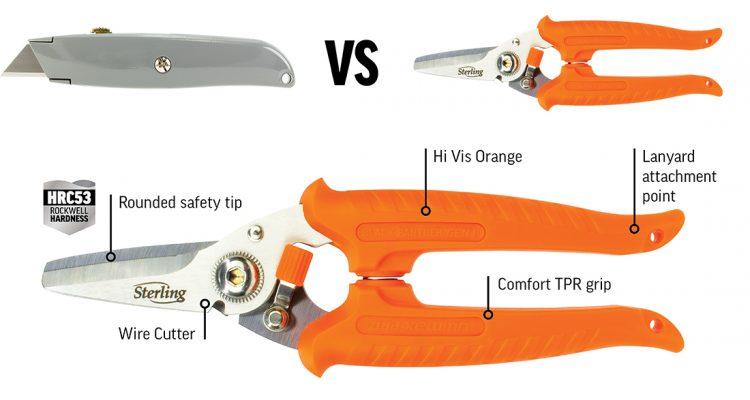

Sterling’s range of snips offer an effective solution to the use of knives, significantly reducing the risk of injury. They offer various benefits in making this a very worthy “all-purpose tool.” Sterling’s expertly designed snips are built to withstand the harshest of environments and claim to be able to handle anything thrown at them.

Benefits of Snips vs Knives

• Snips often have rounded points for extra safety that eliminates the risk of puncture injuries when in the closed position.

• They feature a secure latch that locks the blades when not in use. Knives do not have the same features.

• Snips eliminate the slashing movement and prevent cutting in the direction of the user.

• Snips eliminate excessive force required when blades become dull.

• Snips have more versatility with a wide cutting application range that includes paper, light sheet metal, rubber, Kevlar and electrical cabling. Standard knives do not have the same versatility.

• Snips’ use of mechanical cutting offers more control and precision due to their squeezing action motion, instantly appearing more attractive than knife use.

• Snips may also result in decreased injury from less experienced users due to the different motion from knives.

Sterling’s Black Panther Industrial Snips are a particular highlight with a number of unique features designed to keep you safe. Their premium Japanese stainless steel blades are precision engineered that produce a sharp edge and have corrosion resistance. They have been designed with longevity and durability in mind with the blades hardened to 53 Rockwell and run the complete length of the handle. The serrated bottom blade grips onto material offering accuracy, better control and cleaner cuts. The snips also feature a spring-loaded mechanism that provides easy, smooth cuts helping the blades return to the open position and reducing hand fatigue. Furthermore, there is also the option of orange high visibility handles, making the product more easily discernible from most backgrounds and identifiable as a safety tool.

Overall, the evidence seems to speak for itself that snips are a game-changer in offering an effective solution for the cutting of sharp objects. The team of highly skilled experts at Motion are available to offer advice and recommend the best Sterling products to suit the specific needs of customers. Designed with a user-friendly approach, this delivers on Motion’s promise of solution-based design and quality.

Key features of Black Panther Gen II Rounded Tip Industrial Snips

• New safety orange snip handles – these hi-vis orange handles are easy to identify as a safety tool and discernible against most backgrounds.

• ALL new lanyard holes for tool tethering attachments when working at heights.

• Packaged in compostable bulk packaging, 100% recyclable – perfect for use in bulk stores, warehouses and vending machines.

• Quality Japanese 420J2 rounded tip stainless steel blades – corrosion resistant in industrial environments.

• Blades are hardened to 53HRC.

• Aluminium Free – for hazardous work environments.

• Ideal knife replacement tool.

• Anti-slip comfort grip handles made from impact and solvent resistant TPR material.

• Ideal for various applications including wire, aluminium, sheet metal, carpet, leather, rubber, gardening, food prep, camping and more.

• Convenient wire cutter for light gauge wire and cable up to Ø2.5mm.

• Smooth, resistance free mechanism for easy and precise cutting.

References

- https://www.worksafe.act.gov.au/health-and-safety-portal/safety-by-industry/hospitality-and-tourism/cuts

- https://www.worksafe.qld.gov.au/safety-and-prevention/hazards/workplace-hazards/dangers-in-your-workplace/knives-at-work