The waste management and recycling industry heavily relies on machinery to handle and process waste. In this sector, couplings play a crucial role, as they connect different components and transmit power between them. However, due to the harsh conditions that exist, including shock loads, high temperatures, and abrasive materials, couplings must be robust and of high quality to ensure reliability and efficiency.

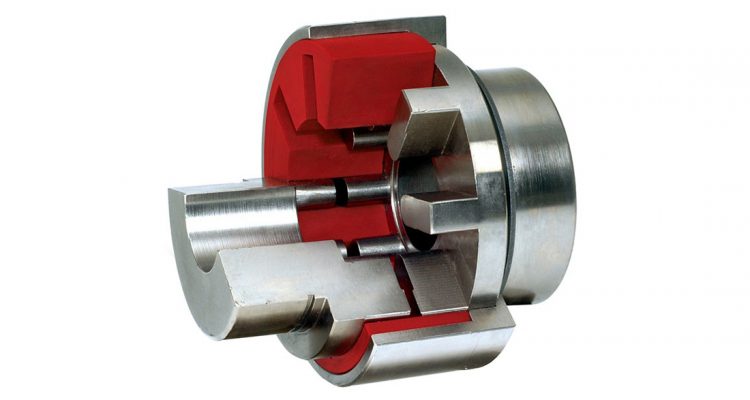

Timken, a global leader in bearings and mechanical power transmission, is trailblazing with their Quick-Flex® (QF) couplings, which are a valuable solution in this industry. The couplings are easy to install, require no lubrication, and can help reduce mechanical stress on equipment. Brad Hudson, a Key Account Executive with Motion and a 35-year veteran of the industry, explains how Timken couplings have been integrated into the sector.

“The coupling is versatile and can be used to connect and transmit torque between drive motors and various equipment. As long as the torque rating matches the equipment being used, Timken QF couplings can be installed,” Brad says. When there is a large torque load, a more robust coupling may be necessary, but for most applications, the Timken QF coupling is an excellent solution.

The Timken QF coupling has been specially designed so that only one component needs replacing if the urethane element fails, rather than the whole machine. “The fitter only needs to remove the cover, clean it out, and replace the element with a new one, before putting the cover back on and getting the machinery up and running again within 30 minutes,” says Brad. This contrasts with a long and complex process which may result in a day of downtime for the customer. As Brad points out, by using Timken QF couplings, this is a low maintenance, cost saving solution where customers are saving valuable downtime costs and being way more efficient.

In addition to their use in the waste management and recycling industry, Timken QF® couplings have proven to be a reliable and cost-effective solution in a variety of industries, from mining and construction to power generation and marine applications. These couplings offer a high degree of flexibility and can accommodate angular, parallel, and axial misalignment, making them ideal for use in harsh and demanding environments.

The benefits of Timken couplings are evident, as they offer an array of advantages to customers. With their global presence and expertise in bearings and mechanical power transmission, Timken is a renowned company in the industry. Moreover, Brad Hudson’s 35 years with Motion is a testament to their commitment to providing high-quality solutions to their clients. As Brad explains, “Timken is a strategic supply partner of Motion, with their solutions readily available on our shelves.” Thus, Motion is an excellent partner for companies in this sector, offering valuable insights and support to ensure their clients’ success.

Timken Coupling Highlights

- Minimise downtime and replacement costs

- No lubrication and low maintenance

- Rely on a trustworthy company

- Need minimal spare parts

- Capable of handling high speeds and high torque

- Built to last even in the harshest environments