Bulk handling equipment such as feeders and conveyors are essential to mines and quarries; they enable the transfer of materials from one stage of the process to the next. However, the drives that power these conveying systems need to be robust and hard wearing enough to withstand the rigours of their application.

Among the challenges posed to gear units in these applications is the dusty environment, high load shocks caused by material drops and the requirement to have a high breaking torque at start-up. With a long history in producing and distributing gearboxes suitable to the Australian mining sector, Bonfiglioli is well placed to advise and assist customers with heavy-duty applications such as these. They are also a strategic partner of Motion Australia, meaning customers stand to benefit from the expertise of experienced drive engineers from both companies.

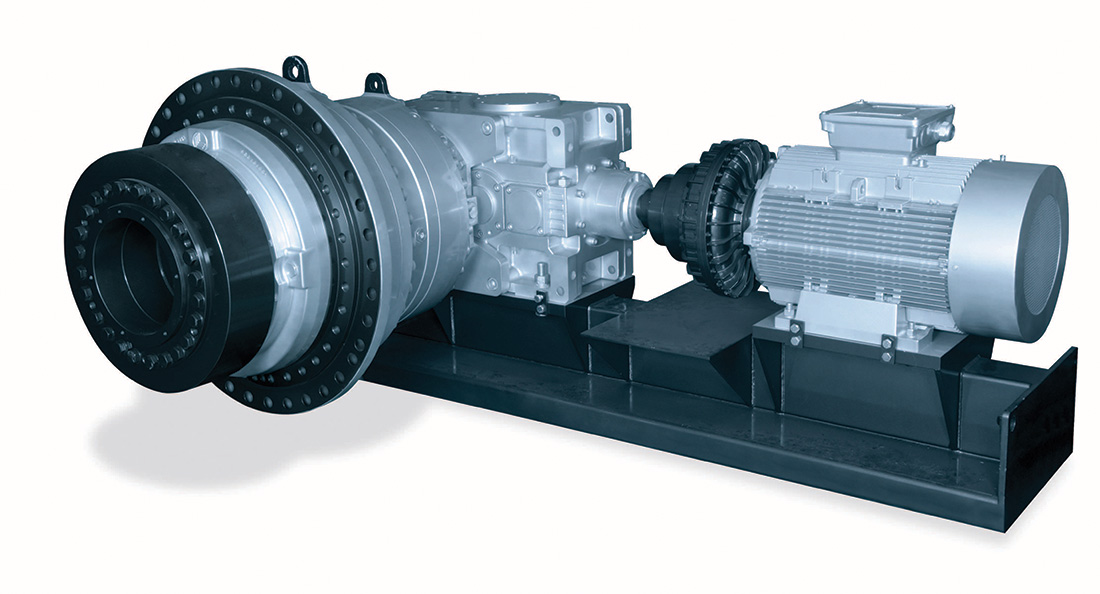

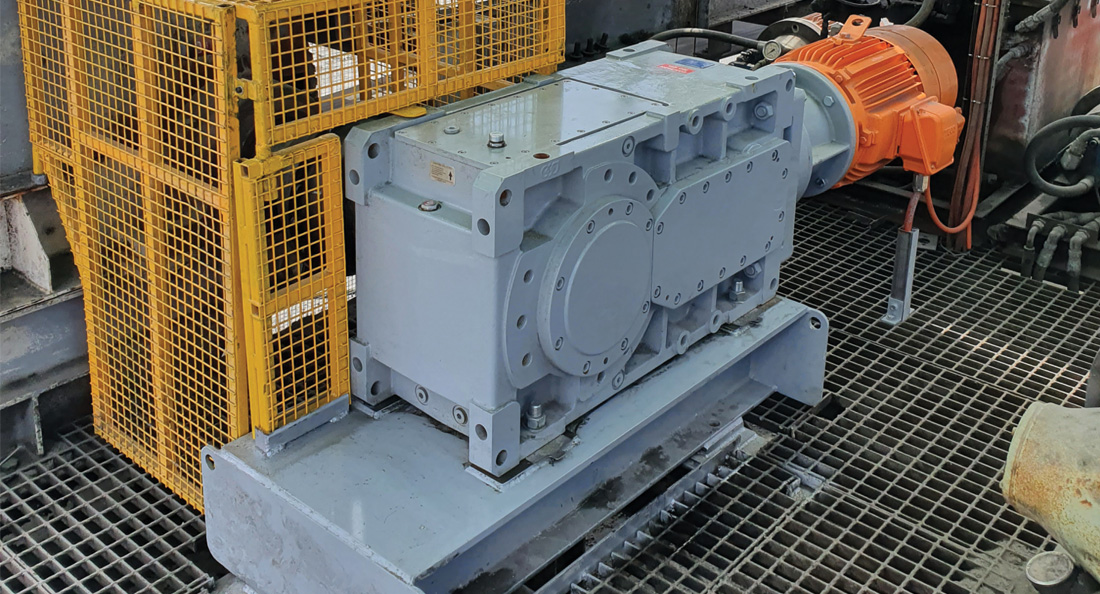

To support feeder and conveyor applications, the Bonfiglioli HDO Series Helical Bevel Heavy Duty Gear Units have been designed with special features to ensure their robustness, reliability, and longevity. These features include a high output torque, mounting flexibility and the ability to operate in explosive atmospheres (they are ATEX certified).

The HDO Helical Bevel Heavy Duty Gear Units are also completely customisable. These gear units can be provided as complete solutions for feeders and conveyors that integrate base plates and torque arms. They’re protected with paints and seals to simplify machine design and protect them from the tough environments in which they operate. Customers can also choose from a wide range of invertors for tuning the operating speeds of feeders and conveyors, thereby reducing energy consumption.

Additionally, Bonfiglioli’s gearboxes are modular, allowing for easy installation and change outs. This also means that Bonfiglioli can cater to local demand by maintaining stock of the gearbox components. They work with Motion Australia to ensure critical stock is stockpiled and units can be custom-built to meet the demands of customers in the mining and quarrying sectors.

Before selecting a heavy-duty gear unit, it’s essential that customers make sure their supplier and the solution meets the brief in terms of quality. Through Motion Australia’s branch network, customers have access to Bonfiglioli’s high quality HDO series. Customers can ask their local branch for advice on the most suitable gear unit for their application. The HDO series is just one solution that Bonfiglioli has available for the mine and quarry industries.

Benefits of the HDO series include

- Highly transmissible power

- Robustness

- Reliability

- Mounting flexibility

- Usable in explosive environments

- Certification

- Long service life

- Low maintenance costs

- Versatility with modular system

- After-sales service and maintenance

- Customisable – can add accessories and there are a range of options to choose from

Key features

- Spheroidal cast iron housing

- I/O shaft planarity and gearbox symmetry

- Wide range of options and accessories

- High design standards

- Atex – gearbox for explosive environments 2G/2D

Options available

- Fan cooling, cooling coil, oil heater

- External cooling unit

- Backstop

- Forced lubrication

- Temperature and oil level sensors

- Drywell

- Taconite seals

- ATEX certification for explosive environments