The materials extracted from quarrying operations are often transferred to a processing plant, manufacturing facility, warehouse, or workshop where they will be transformed into products. Regardless of where these materials end up, fresh air in these spaces is essential for limiting exposure to the dirt and dust that come with them.

SafeWork Australia has issued a warning to employers about the health safety risks associated with working in conditions that have inadequate airflow. By law, Australian employers are now required to ensure their working environment has an effective ventilation system.

In a nutshell, ventilation means replacing contaminated air with fresh air. But when it comes to creating safe, healthy working environments, it’s important for site managers to equip their workspaces with powerful, efficient, heavy-duty mechanical ventilation systems, according to Troy Lopez, General Manager at Fanmaster.

“Improper ventilation causes stress on the body, inducing discomfort, exhaustion, and heat stroke in workers. Industrial activities such as welding, drilling, grinding, and even transporting materials emit harmful dust, dirt, and contaminants that can cause long-term respiratory and neurological diseases,” he says.

Fortunately, the ventilation, cooling, and extraction experts at Fanmaster have site managers covered with a few effective methods for ventilating industrial workplaces:

1. Industrial fans for air circulation

Fans can make people feel cooler and more comfortable due to the breezy, chilling effect they create. Fans that improve air quality by extracting contaminants and stale air include:

• Mobile Mancoolers: These portable fans that extract contaminants are often used in the mining and quarrying industries because they are suitable for confined spaces on underground operations

• Commercial pedestal fans: Available in a wide range of sizes

• Fixed wall fans: Ideal for use in a range of working environments

• High-volume-low-speed (HVLS) ceiling fans: For keeping air moving in industrial workspaces

2. Mechanical ventilation

Ventilation methods work by expelling stale air and introducing fresh air from outside. These units can be either fixed or portable. Fixed ventilation methods include hooded roof fans, wall exhaust fans, axial flow fans, and industrial louvered fans designed for industrial sites and agricultural buildings. Portable ventilation units include portable fume collectors, mobile man coolers and compact air blasters.

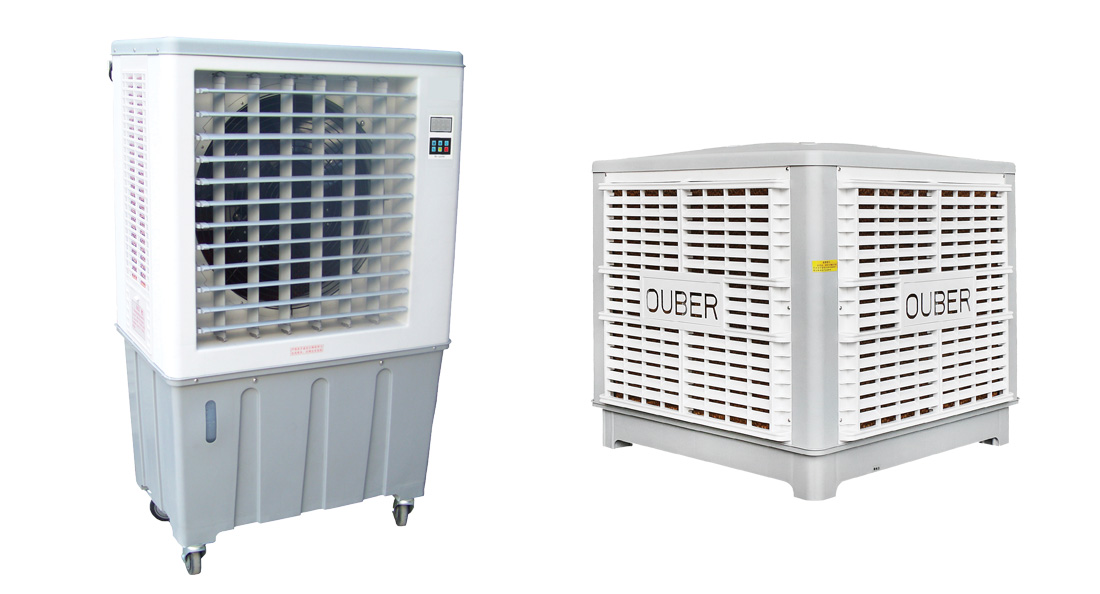

3. Coolers

Cooling units such as evaporative coolers and air conditioners also help improve air quality and air circulation through movement and distribution. Another option is that of misting fans – which supply a fine mist (which quickly evaporates) during operation, helping to create cooling breezes.

Which option works best for you?

In some cases, working environments might require a range of solutions to ensure quality air flow. The best way to start is by speaking to an expert to determine the best solution for your situation.

Fanmaster has been an Australian family-owned-and-operated business for over 21 years. The company specialises in the import and manufacture of cooling, heating, ventilation, and extraction systems and offers extensive knowledge in their field to the industrial sector.

As a supplier to Motion Australia’s network of businesses, this adds an additional layer of technical support and mechanical engineering know-how to Fanmaster’s mission to bring fresh air and thermal comfort to Australian industry.

Visit your local Motion Australia branch and speak to a technical representative today to find the best ventilation system for your quarry.

Featured Product: Fanmaster Hooded Roof Fan

The Fanmaster IHR8-22-6-3 Hooded roof fan extracts heat, smoke, dust, or fumes from buildings. When used in conjunction with coolers, the hooded roof fan helps to keep the temperature down during hot Australian summers.

• Base and body made from high quality steel

• Aluminium cap

• Weatherproof design