The ROCOL brand’s range of food grade lubricants have been making waves with major food chains in recent years. According to Steve Keown, “ROCOL’s slightly higher price point is more than compensated for by the quality of their products.”

“Without reliable, certifiable lubrication products, it is certain that manufacturers will run into production issues,” says the CBC National Product Managers for ITW Polymers and Fluids.

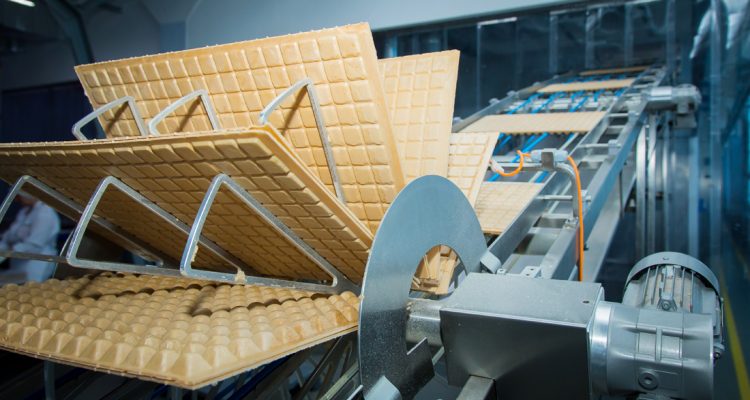

ROCOL’s Foodlube product range includes hydraulic oils, gearbox oils, compressor oils, and grease for chains, sprockets, and bearings. All ROCOL Foodlube products are food-grade, which means they are suitable for food production or clean manufacturing environments.

“ROCOL manufacture high-end lubricants that check every box for certifications and in some cases increase the performance of components. So, as soon as a procurement manager unrolls ROCOL’s extensive list of certifications, there is automatic assurance that they can sleep at night knowing certifications are being met and production is running smoothly.”

The products are NSF H1 registered in case of accidental contact with food products and use only FDA approved ingredients, free from mineral hydrocarbons, GMO’s and nut oils and their derivatives.

“It is of the utmost importance that food-grade lubricants meet several benchmarks; such as ‘food-specific’ certifications for the many applications at the manufacturers site,” asserts Steve. “But it is also important to ensure that consistent supply-chain is available. Certain products are hard to import these days due to travel restrictions, but ROCOL has an extremely high-tech Australian-based manufacturing facility, so their Australian manufactured products are consistently available with reliability.”

Although, not Australian-owned, ROCOL has an interesting history to draw upon.

The ROCOL brand was acquired by Illinois Tool Works (ITW) in 1999, but its origins date back to 1878 when Russian chemist Victor Ivanovitch Ragosine developed his first non-corrosive lubricating oil, which he subsequently distributed across Europe as the first product of its kind.

A businessman from Leeds eventually bought out Ragosine and Company Ltd, or ‘ROCOL’ for short, and turned it into one of the most prominent industrial lubricant companies in the world. Today, ROCOL maintains their reputation for producing innovative high-quality industrial lubricants that are made with premium ingredients and are widely recognised for their longevity.

Connor Devereux, Brand Manager for Heavy Industry at ITW Polymers & Fluids outlines some of the key products in the ROCOL Foodlube range of products, offering ‘a complete lubrication solution’ for customers who value the performance of their equipment.

ROCOL Foodlube Hi Torque

A range of high performance fully synthetic gear oils incorporating ROCOLS unique start up protection system (SUPS) and anti-wear additives, the Foodlube Hi Torque products provide maximum lubrication and protection in all types of gearboxes, according to Connor.

“Our Hi-Torque gearbox oils can significantly extend change out intervals for a more efficient maintenance process and machine availability,” says Connor.

All viscosities of ROCOL Foodlube Hi-Torque gearbox oils feature:

- SUPS – a unique protection package for gear teeth on start up and in use.

- Outstanding load carrying performance: FZG load stage 12

- Excellent anti-wear performance – no need for additional additive treatments

ROCOL Foodlube Hi Power

A range of high performance fully synthetic, food grade oils for compressor, hydraulics, vacuum pump and airline systems. ROCOL Foodlube Hi Power fluids can also be used for chain & gearbox applications in extreme cold temperature applications (as low as minus 50°C).

All viscosities of ROCOL Foodlube Hi Power hydraulic oils feature:

- Enhanced oxidation stability

- Extremely low sludge build up

- Minimal foaming

- Unique L-CO system which reduces carry over

ROCOL Foodlube Aerosols

ROCOL Foodlube aerosols cover wide range of applications and all include ROCOL’s unique DETEX® technology so are essential for those jobs beyond the “red line” in any food plant.

“Our DETEX® metal detectable components for aerosols are designed to assist food processing plants in meeting strict HACCP requirements,” explains Connor. “All blue DETEX®, removable plastic components are metal detectable and capable of detection by most metal detection equipment and x-ray machines.”

ROCOL Foodlube Spray

Foodlube Spray is a high-performance, versatile lubricant spray for all-round light lubrication of small bearings, pins, bushes, and slides.

“Our spray is also suitable for use as a food-grade drilling, tapping and cutting lubricant, particularly when maintenance has to be carried out in the process area beyond what could be considered the red line,” says Connor.

Customers can rely on CBC as a distributor of the full range of ROCOL Foodlube products and for consultation on what products to use for specific applications.

“We will go to your plant and look at everything from the lubricants in your gearbox, to hydraulic systems, compressors, air systems and packaging,” says Steve. “We look to take the pain away from maintenance staff by presenting a reliable premium solution and working with the team at ROCOL to ensure customers are getting the right lubricant for the job.”