According to Leon Stefanec, National Business Development Manager for Food and Beverage at Motion Australia, the average processing plant will likely replace 500 to 1,000 feet of conveyor chain every maintenance cycle. With this in mind, designing chain product with low-friction, stress resistant properties is imperative for industrial part manufacturers servicing the Australian market.

Unit handling for beverage packaging is generally a high-speed operation, relying on the ability to keep things moving without the risk of equipment failure or unplanned repair time. Whether it be cases of glass bottles, cartons or cans, Motion Australia recommends the TableTop® chain from Rexnord as a cost-effective long-term solution.

“There are a number of major beverage manufacturers in Australia that source this Rexnord chain product through Motion Australia’s supply network,” Leon says. “Everything from beer to soft drink and juice, whether it’s bottle or in a can – TableTop® chain is a versatile product and is extremely popular with our customers in that sector.”

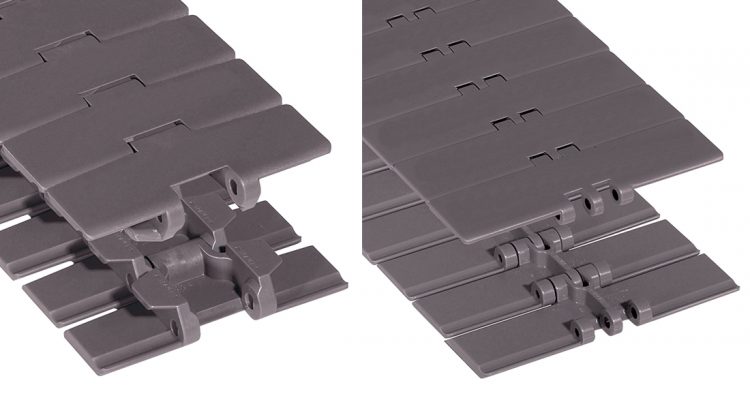

Matt Crehan, National Product Manager at Rexnord, explains that the TableTop® chain is held together with a stainless-steel pin on a central hinge. It can run horizontally on sprockets of various sizes, up to speeds of 100 metres per minute.

“The TableTop® chain comes in set widths for multiple strand and variable speed conveyors, which is one of the key features that sets it apart,” he elaborates. “There are other chain varieties under the FlatTop® portfolio, but TableTop® is best suited to high-strength and high-speed applications such as bottling.”

The heavy washdown procedures of the food-safe environments calls for a high level of resistance to frequent, pressurised moisture. To combat this, Rexnord has utilised acetal and specialty plastic materials in addition to the stainless steel and carbon offering, as they are generally easier to maintain for this setting. They also run at a much lower volume.

“The standard polyacetal material can withstand temperatures of up to 65°C in hot water,” Matt says. “It is also available in a range of other materials, including polypropene, which can withstand up to 105°C. The range is quite diverse to address a myriad of heat and chemical resistance requirements for different applications.”

Further, the pin retention elements holding the chain in place can be easily removed with a screwdriver for routine sterilising. The chain is available in both straight and side-flexing styles, and the open hinge design offers ease for swapping out or adding parts as needed.

In Leon’s experience, while the basic function of most conveyor chain is the same, investing in the best quality product will save manufacturers immensely in the long run. Since 1938, Rexnord have been delivering on durability and leading-edge solutions, backed by extensive research and stringent testing procedures.

“We have an established relationship with Rexnord and successfully work with them to deliver on high-profile customer requirements,” he says. “We have seen phenomenal growth with their business over the last year, and a large part of that is because we approach hands-on field work as a unified team.”

Fred the Farmer says, ‘forget to clean and you’ll have a faulty machine!’

In addition to grease and debris, any spillage of beer, juice or soft drink can cause endless problems for a conveying system, such as:

• Contamination or damage to the product

• Increased horsepower requirements

• Chain pulsation

• Excessive wear on joints and hinges

• Rapid wear on wear strips

• Accelerated sprocket tooth wear

To avoid costly downtime due to maintenance and repair, consult your product manual for the correct cleaning frequency and solution type.