Before being acquired by Motion Australia in 2019, CRAM began with a team of four hydraulic specialists, operating out of a small workshop in Unanderra, New South Wales.

Today, CRAM is a globally scaled and recognised brand that incorporates the collective knowledge of 1800 employees working at more than 180 locations across Australia, New Zealand, and South East Asia.

“Our mission is to provide superior engineering services and products that will exceed customer expectations and impress the competition,” says Ryan Kendrigan, General Manager at CRAM. “We have a good mix of working with OEM products in combination with our own manufacturing. Our bespoke manufacturing provides high quality engineered solutions to our customers who are operators and contactors within the industrial space.”

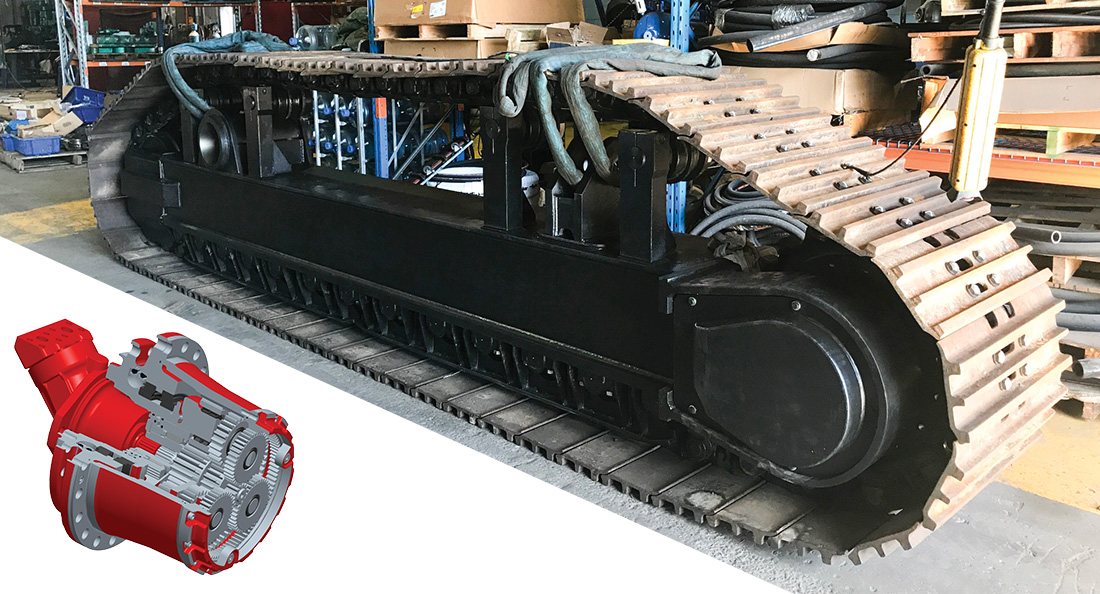

The company specialises in high level industrial engineering and design— supplying products in the fields of fluid power and hydraulics. Additionally, CRAM offers full service in-house design and drafting services which include fabrication, maintenance, refurbishments, repairs, and overhauls.

As a full-service engineering solutions provider, CRAM is no stranger to the mining sector— facilitating the supply, refurbishment repair of blast hole drill units and undercarriage components, as well as all other mechanical, structural, and fluid power componentry such as chain, rollers, and sprockets.

CRAM’s in-house fabrication workshop offers world-class engineering services that are unparalleled in the mining and heavy industrial markets.

“We have a dedicated engineering projects team that manages the design and manufacturing of a wide range of mechanical, fluid power, and electro-hydraulic solutions,” says Ryan. “Our mechanical and fluid power engineers can perform a comprehensive analysis of fluid power systems, mechanical componentry, and structural analysis.”

“Our CP Engineers can certify all calculations for our clients by Australian Engineering Standards and Mining Design Guidelines,” he elaborates. “Then we present the client with a full-service solution package which includes on-site installation, training, and follow-up assessment to see how the equipment is performing down the track.”

A team of electro-hydraulic engineers designs and builds electronic control systems that are tailored for the specific requirements of different types of hydraulic applications.

“Our in-house design capabilities allow us to manufacture complete machines as well as reverse engineer existing machines for repairs and upgrades,” says Ryan. “We test all our projects to the highest standards and ensure our clients have assurance that their equipment is certified and compliant.”

CRAM’s management systems are certified to ISO 9001 Quality Management Systems, AS/NZS 4801 and accredited to AS/NZS ISO/IEC 17020 for the operation of various types of inspections. In addition to this, the CRAM team practices a ‘Zero Harm’ standard for environmental protection and safety.

“We are a company that customers can recommend, and employees can be proud to work for,” concludes Ryan. “Our team is compelled to produce reliable machinery that is fuelled by innovation and a passion for engineering and driven by the needs of our customers.”