Digitalisation and component monitoring are quickly becoming integral aspects to present-day mining environments. Processes such as cataloguing, inventory control, product lifespan assessment, and design initiatives can be significantly bolstered by the incorporation of integrated software programs. The ability to compare and contrast belting solutions on large plants can ensure that the best application is fitted to the correct tension, pull and alignment.

The Gates® Design Power™ digital platform offers a full spectrum overview for customers, engineers, OEMs and suppliers to collaborate and assess the performance of various belt models on-site. CBC has recently been working alongside a large natural gas producer in Queensland to integrate this software as a monitoring solution on multiple Gates® PowerGrip™ GT4™ belts that are currently in use.

Rob Michelson, National Product Manager for Belts at Motion Australia, says that generating automated feedback on the performance of the PowerGrip™ GT4s™ has helped to identify their benefits, and suitability to a range of applications on mining, quarrying and gas extraction sites.

“Gates is fairly unique in their implementation of this software, which provides us with an added service that we can offer customers,” he explains. “Being able to pull up those data sheets when doing complete overview and analysis of each drive makes the process a lot more streamlined, and ensures attention to detail where it counts.”

Essentially, the Design Power suite comprises of multiple tools to support the engineering and specification of belt-drive systems. These tools include the upgraded version of Gates® Design IQ™, and Design Flex Pro™ modules. The user-friendly functionality applies over a century of knowledge on belting technology in a sophisticated framework to calculate dimensions, tension, transmission capacity, energy and cost savings.

“This software infrastructure allows us at CBC to conduct ongoing drive analysis for the customer,” explains James Darrach, from the CBC Technical Services team. “We gather the technical details on whichever product they are using, assess their suitability in terms of size et cetera, then make educated recommendations to improve the wear life and efficiency.”

CBC’s customer in Queensland has done a full upgrade on drive solutions across their operations, implementing the Gates® PowerGrip™ GT4™ rubber synchronous belts. According to James, the feedback has been overwhelmingly positive – a testament to the strong supply partnership between Motion Australia and Gates that has developed over many years.

“Since we started doing work with these gas plants, Gates has been very supportive,” he reflects. “They are always happy to work with us on the design side of things, and the quality of their products really is outstanding, which we have seen through these ongoing applications in the mining industry.”

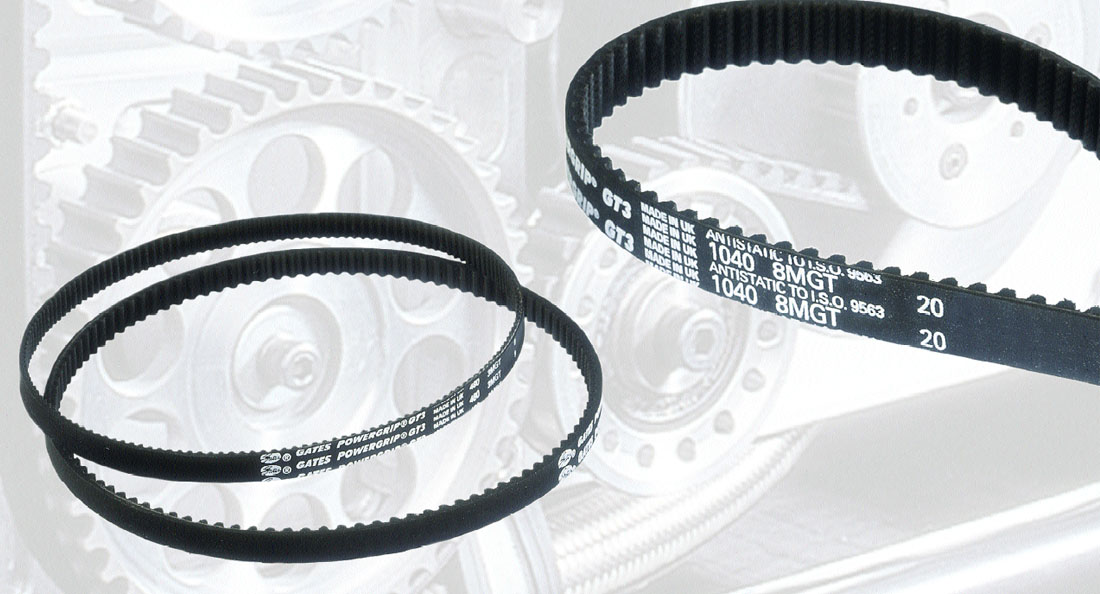

The PowerGrip™ GT4™ range has been expertly engineered with both durability and low maintenance in mind. Delivering improved performance on previous models, the 8MGT and 14MGT pitches boast increased load capacities, broader temperature range tolerance, and are constructed from environmentally friendly materials. According to Rob, these benefits render this product a clear choice for industrial businesses operating in mining, construction, forestry, textile and food processing industries.

“Gates provides a range of different belts for varied, specific applications and the GT4 is up there in the top of the range as far as power goes. What that means is the belt, instead of being so wide, is narrower and gives less pressure on the bearings and other parts. Getting the load closer to the bearing is also an advantage in terms of speed.”

Without the need for lubrication or periodic re-tensioning, these drive belts eliminate a significant maintenance cost over the product lifespan. Not only does the lighter weight improve ergonomic safety due to reduced strain on installation, it also minimises noise factor because less air is trapped underneath the rubber.

Elaborating on this, James says, “a huge benefit of these belts is that they can replace chain applications in some circumstances, which mitigates a lot of the effort and cost of lubrication. There is just as much – if not more – power with this more lightweight product, and you are not constantly having to clean up grease. It is also not going to rust or corrode like a chain would.”

Representatives from CBC will frequently collaborate with Gates team members to utilise the Design Power portfolio and conduct joint visits to customer sites. The ethos behind this partnership is based on delivering cost-effective and long-lasting product solutions to the Australian industrial sector, ensuring full satisfaction and evolving solutions to meet market needs.

“Our relationship with Gates is built on many years of trust and great communication,” Rob says. “Having been around for over 100 years, they have always been at the forefront of new belting technology. From products like the GT4, to the innovative Poly Chain®, their belts are unparalleled in terms of horsepower ratings and power transmission capabilities.”

What makes the PowerGrip™ GT4™ stand out?

- Made with environmentally friendly materials

- No lubrication or re-tensioning required

- Temperature tolerance between -40°C – +120°C

- Rust free and improved chemical resistance