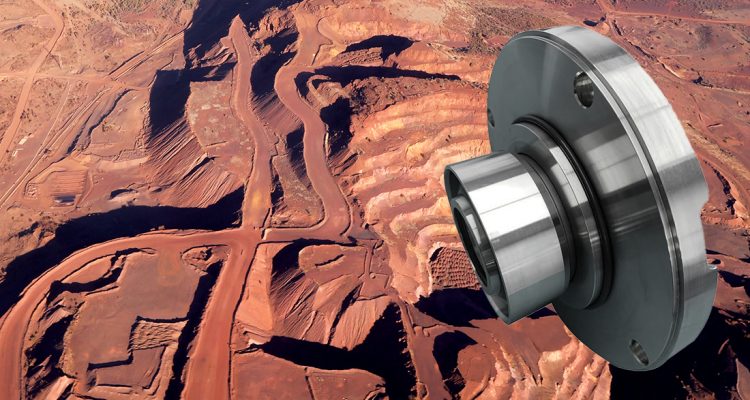

Lance Brett has been working in mechanical seals for over 35 years. Now a National Product Manager at Seal Innovations, he is excited to bring their new Heavy Duty Slurry Seals onto the market for Australian customers.

“We’re really pleased with the quality of these seals and how they stand up in terms of wear life and reliability,” he enthuses. “It perfectly complements the rest of our product range and offers new potential for our involvement in the mining and quarrying sectors.”

The role of a sealing application cannot be overlooked, especially in resources where they act to secure valuable materials while they are being processed. Slurry is formed when water combines with ferrous and non-ferrous raw material, such as rock and soil between 1mm and 25mm thick. In mining, there are several types of pumps used in the transport of large volumes of slurry to mineral processing plants, where it then undergoes a separation process.

The solids within slurry can often prove highly abrasive, contributing to the accelerated wear life of critical parts, including seals. This problem can be amplified in a hyper saline environment, which may cause crystallisation of material around the surface.

The new Heavy Duty Slurry Pump Seal from Seal Innovations can withstand the harshest operating environments, providing maximum seal life in mining, quarrying and dewatering applications. The abrasion resistant metal components, along with silicone carbide faces, create an open design which reduces flush water and product dilution.

“This seal unit has been specifically designed for handling slurry concentration of up to 40 per cent solids by weight,” explains Lance. “It is an incredibly robust construct mechanical seal which is best suited to rugged mining and quarrying environments. Differently to standard O-ring designs, it is a rotating assembly, offering accurate installation with no special tools required.”

What’s more, the smooth, elastomer-coated cone spring increases the product’s reliability with an even spring load to the seal’s faces. This ensures minimal wear or clogging, in operating pressures up to 300 psig (20.7 bar).

“We have introduced this product to fill a prominent need in the market for mining-suited slurry pump parts,” Lance elaborates. “It’s a really exciting addition to our portfolio of industry leading seal products, and we’re already taking it to some of our most valued customers as an upgrade solution on troublesome equipment.”

He adds that, in addition to a comprehensive catalogue of sealing products, the business also provides aftermarket engineering and repair services from some of their centrally located branches.

“We can repair and overhaul slurry pump units as well as seals from our workshop in Brisbane, and we can repair any type of slurry seal from our Melbourne workshop. Everything is repaired back to manufacturer specification, and thoroughly tested for performance before re-entering the field.”

Technicians from Seal Innovations regularly visit customer sites, utilising their comprehensive knowledge of seal engineering to carry out audits, training and installation services. In line with their motto – “keep industry moving” – they strive to meet each customer’s unique requirements and offer a one-stop-shop for all sealing needs.

Features of the new Heavy Duty Slurry Seal

• Line-on-line seal face design

• Fully sintered, interchangeable silicon carbide faces

• Clamp collar

• Anti-jamming drive washers

• Smooth, elastomer coated anti-clogging cone spring

• All static secondary gaskets

• Quench Containment Device (QCD) for a water or Syntheic Lub Device (SLD)