Sustained operation and output on a mine or quarrying site is highly dependent on the durability of genuine parts. In the complex framework of heavy weight mining and transporting operations, holding it all together are strong bearing components. To ensure long machinery lifecycle and avoid downtime due to part failure, these bearings need to be reliable, defensive against harsh environmental factors, and easy to replace.

Sheree Munnik, Motion Australia’s Key Account Executive for Mining in Perth, works alongside Schaeffler to supply a local gearbox repair business with tailored bearing solutions. She explains that making sure this customer receives high-quality and suited components is paramount, as they have several large companies relying on their services in an ongoing capacity.

“This particular customer has many divisions, and they support a large sector of the mining industry,” she says. “I work quite closely with their gearbox division, who are renowned aftermarket repairers of vibrating machinery in the mining sector. They have been coming to CBC for over 10 years to source componentry for their designs, so we have built up a good rapport and level of trust.”

“This particular business has built a strong reputation on the quality of their service offering,” Sheree elaborates. “Lots of people rely on them thanks to the credibility and quality of their work. It is very much focused on extending the lifetime of machinery, particularly gearboxes, to help their customers save time and money.”

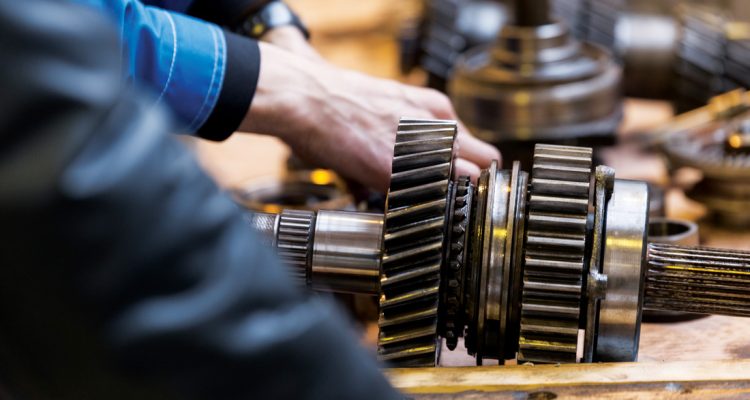

The primary use of this vibrational equipment is to carry out screening processes, as part of the crushing and sorting of raw materials into different sizes. These screening machines move in all directions – back and forth linear motion, circular rotation and elliptical movement – so require purpose-built spherical roller bearings, such as Schaeffler’s FAG T41Ds.

“The T41Ds are high-quality spherical roller bearings that perform well under extreme pressure and stresses,” explains Sheree. “Because there is a lot of vibrating going on across mine plants, this bearing is made stronger to avoid slipping and consequential breakage. They need to have that long-term resistance capacity to achieve full asset lifecycle.”

These bearings feature Schaeffler’s innovative surface treatment, Durotect CK. This hard chromium coating is designed to combat the harsh contaminants on mining sites as well as potential fretting corrosion. While standard bearings tend to develop peaks on their surface where extreme pressure has occurred, the Durotect hard coating on the bore alleviates those peaks for a smoother, consistent surface.

Heavy industry conditions, such as repeated impact, dust pollution, dirt and grime can all negatively affect the lifespan of machinery parts, so incorporating defensive coatings on these bearings gives Schaeffler an edge within the mining and quarrying markets.

“Since Schaeffler introduced the Durotect feature on these spherical roller bearings, we have had a lot of great feedback from customers,” reflects Sheree. “They are an exceptional bearing manufacturer. They are also well-known to the industrial market for going out of their way to understand niche applications and carrying out research and development (R&D) to meet those specifications.”

Delivering expert and considered componentry solutions requires Motion Australia businesses to have a well‑established and trusting relationship with Premium Supply Partners like Schaeffler. A large part of that process involves Sheree liaising with Schaeffler’s engineer and servicing teams, providing clear communication to the customer around supply processes and the most effective application of the roller bearings.

“Here in WA, we work together closely on collaborative customer visits. Representatives from Schaeffler’s team regularly come with me to visit customer sites and carry out assessments. We find this is extremely beneficial for the customer because they gain an understanding of how the parts manufacturing works, their process, and production schedules. They get to see first-hand how their requirements are being met behind the scenes. It gives them full visibility on the process.”

“CBC works closely with Schaeffler to offer services in terms of monitoring, and tracking the wear of these units. We support research through case studies and make sure that we are available to assist, should any red flags arise,” Sheree explains.

The T41D bearings come under Schaeffler’s X-Life quality program, ensuring complete satisfaction and peace of mind with regards to their sustained performance. This seal of quality covers heat treatment, surface hardened cages, and tighter dimensional tolerances on every unit sold. The T41Ds offer an increased lifespan when applied on exciter units in vibratory machines, raising the benchmark for industrial bearing products Australia-wide.

This product is available through consultation with a CBC representative, who can carry out detailed assessments and specific application needs of each site. Their continual stock quantities can assure accessibility for part overhauls and monitoring services long-term.

“Motion Australia has been working with Schaeffler for a long time, so we have a very close supply relationship,” Sheree points out. “As one of our Premium Partners, they deliver excellent service on top of extremely high-grade products with guaranteed consistence.”

Why Maddie the Miner recommends Schaeffler T41D Spherical Roller Bearings

- Designed for oscillating load with restricted diameter tolerances

- Temperature resistance up to 200°C

- High performance guarantee with X-Life quality

- Durotect CK limits corrosion and shaft wear

- Tighter OD and ID dimensional tolerances for cleaner fit