Cotton is an important crop that provides employment for more than 10,000 people in New South Wales and the lower climes of Queensland. It is a crop that can be temperamental when being processed, but is also a hardy product that is a staple of the textile and fashion industries. Latest figures show that 3.2 million bales were produced annually between 2014-17 in Australia. It is a multi-billion-dollar industry that relies on hard work, good rainfall, and reliable equipment.

Companies who own the processing plants run their equipment hard and so, have high expectations when it comes to the type of power transmission products they use. The equipment must perform a large amount of work when the crop comes in. Interruptions for maintenance, or worse, equipment failure are to be avoided at all costs. Failure is simply not an option during processing as it will not only eat into the company’s bottom line, but time and reputation can also be negatively impacted.

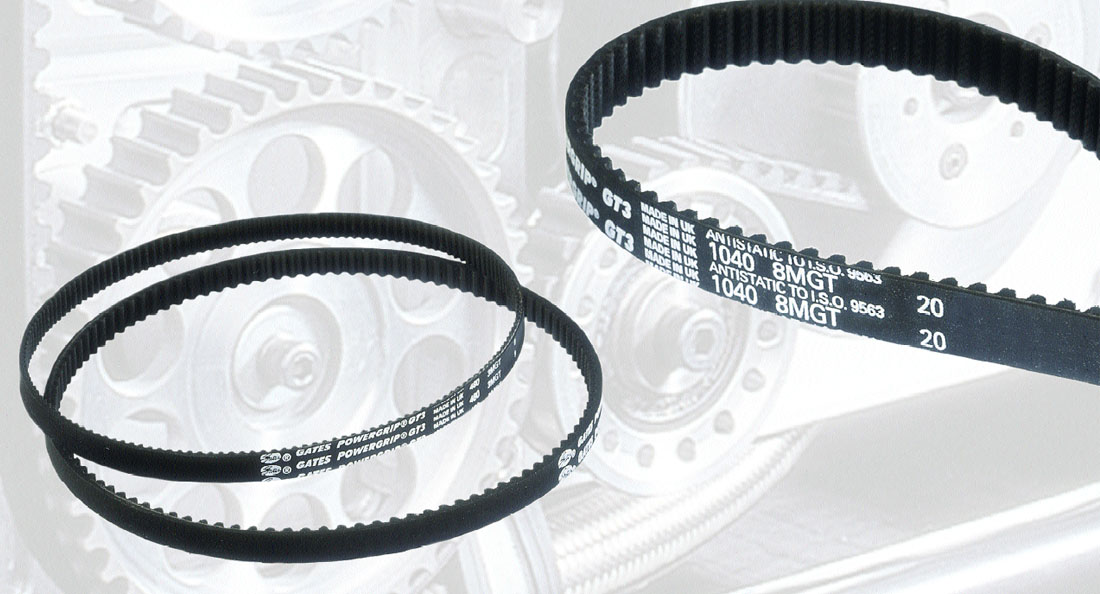

The power transmission drive belts are one of the most critical elements of the cotton processing machine. With low efficiency or just plain unreliable belts, productivity is dramatically affected. The seasonal nature and demands of a cotton ginning plant are such that they are expected to run without interruption for the entire processing period. Therefore, it is imperative that the drive belts, that are critical for effective and efficient power delivery, are in top shape and are capable of handling the pressure of running day in, day out and at optimum capability.

Gates is a company that understands the exacting requirements of cotton processing and supplies high-quality power transmission products to the industry, especially when it comes to v-belts and synchronous (timing) belts. When using Gates Quad Power™ 4 v-belts and Poly Chain® GT™ Carbon™ timing belt products, users benefit from premium construction methods and the use of advanced materials. Customers can eliminate maintenance stoppages when using Gates power transmission products.

Not only are the products well-constructed, but they are capable of replacing some of the more problematic or traditional solutions, such as transmission roller chains.

“The traditional use of chains is no longer the only option,” said Gates National Sales Manager for Power Transmission, Steve Thatcher. “Gates Poly Chain® GT™ Carbon™ timing belts transmit so much torque they can now totally replace troublesome transmission roller chain drives. This allows customers to eliminate maintenance stoppages for things such as chain lubrication and the removal of chain links to correct elongation caused by wear.”

“Gates Poly Chain® GT™ Carbon™ timing belts are more accurate, run faster, are quieter, last longer and are better for the whole working environment.”

As well as having a lot of quality features, another highlight of these belts is there is less mess, according to Thatcher.

“Lubricant required for the roller chain gets everywhere, and when combined with the cotton fibre dust, creates challenges for production floor cleanliness,” he said. “Gates Poly Chain® GT™ Carbon™ timing belts use the most advanced carbon fibre tension cord components to produce a maintenance-free belt with the highest power delivery possible.”

Using the right belt for the application is critical for best drive performance. V-belt drive applications on many sites now use Gates Quad Power™ 4 v-belts. What makes these belts so durable is that they are made from premium rubber blends, as well as the most advanced construction methods. The belts deliver more power than similar versions and can run at temperatures up to 131°C. Its EPDM rubber material doesn’t get sticky and resists hardening to avoid cracking, typical at higher temperatures.

The construction also takes into account the space limitations on most equipment. It offers much higher power density than classical v-belts, which means Quad Power™ 4’s design is more compact, which in return results in reduced drive width, weight and therefore costs.

One final aspect of its design is it features a specially engineered moulded notch shape that reduces bending stresses. Therefore, the belt shows improved flexibility for increased performance on small pulley diameters. This flexibility gives the belt excellent reverse bending properties when backside idlers are used.

They are not only available in all popular sizes as a single belt, but also in the sturdy PowerBand™ execution for high shock-loaded or vibration-prone drives.

The Quad Power™ 4 v-belt can improve drive and power efficiency by three per cent when compared to traditional wrapped belts and return energy cost savings as a consequence. Gates Quad Power™ 4 v-belts are designed to be match-free, maintenance-free and deliver improved power delivery over traditional wrapped belt types.

All of these properties and features are exactly why Gates belts are suitable for such an industry like cotton ginning. They are tough, reliable and can handle harsh environments.