Starting out as a four-person hydraulics workshop in 1994, CRAM is now an internationally recognised engineering company under Motion Australia. Their team of 1,800 employees spans across 180 locations, offering valued support to the mining, manufacturing and fabrication industries.

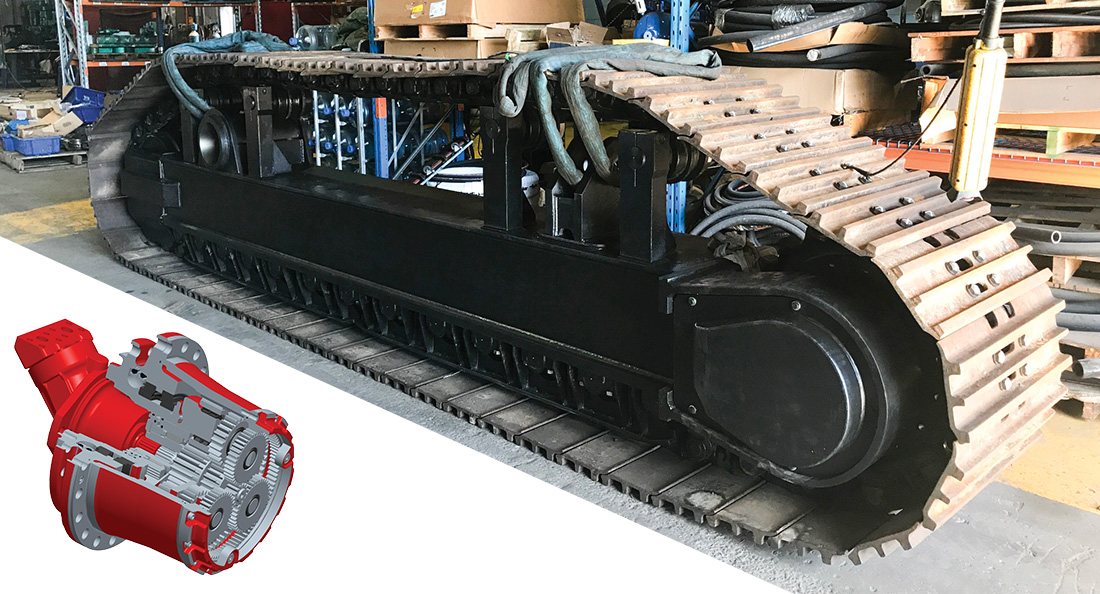

Highly specialised in areas such as fluid power, electro-hydraulic engineering and design, as well as comprehensive maintenance plans, the team at CRAM are dedicated to offering premium support. Their full service in-house design and fabrication workshop boasts unique capabilities including mechanical overhaul and heavy fabrication.

“Our overarching vision is to be a full spectrum provider in making machinery move,” says Ryan Kendrigan, General Manager at CRAM. “We take care of hydraulic and pneumatic projects, their interface with electronics and other industrial support work. We cover machinery components, repair, refurbishment, overhaul – we will come out to site to analyse equipment and see how we can improve it.”

CRAM’s involvement in the food and beverage industry is far-reaching, operating largely in hydraulic, pneumatic and special purpose manufacturing. This often involves on-site visits to install or update production machinery, as well as general services like repair, fitting and welding. Spanning from light services through to bespoke turnkey solutions, CRAM works closely with customers to offer ongoing support.

“The food industry is so diverse,” says Ryan. “We often look at closed loop systems on equipment requires precise positional control. We can take care of anything that requires movement in these specific environments. That could involve welding, pressure vessel piping systems and the ancillary equipment around that. Whether it be mobile equipment on farmland, or the complex array of equipment in processing plants, there are ways that we can provide value and improvement.”

Recent work in a large Australian starch and gluten mill has seen CRAM delivering hand-on support across their industrial sites, including boiler house fittings and upgrades to wheat product dryers. The team also carried out diagnostic services on starch mills, specialised installation of gluten drives, and oxygen cleaning for ethanol processing valves. As Ryan points out, wherever product is being transported or processed, CRAM’s involvement will go a long way.

“What we do is quite varied. On a food processing plant, there are multiple stages that need attention, including milling, drying, extruding, drop shifting, conveying and pumping systems. Because the solutions we provide are so extensive, customers can rely on us to cover many bases, not just one. If we can get involved at those key stages, there will certainly be opportunities to make things more efficient.”

CRAM’s technical framework values compliance with industry standard regulations and a commitment to premium grade product. Their management systems are ISO 9001 and AS/NZS 4801 certified, also meeting the ISO 14001 Environment Management standards.

The company is constantly looking to the future, integrating research and development at every stage of their business growth. Acknowledging the ever-changing market, CRAM pays close attention to customer-specific needs, offering tailored engineering approaches. As a part of Motion Australia’s expansive industrial supply network, they seek to meet world class standards for quality servicing.

“Our long-term goal is to provide holistic services and tangible benefits at each step along the manufacturing line. It is about making it easier for businesses by addressing any major point of movement on site – no matter what the type of motion is, we are always capable of providing value. We are driven by the day-to-day needs of customers, and strive to be the most reliable and accessible option across Australia.”