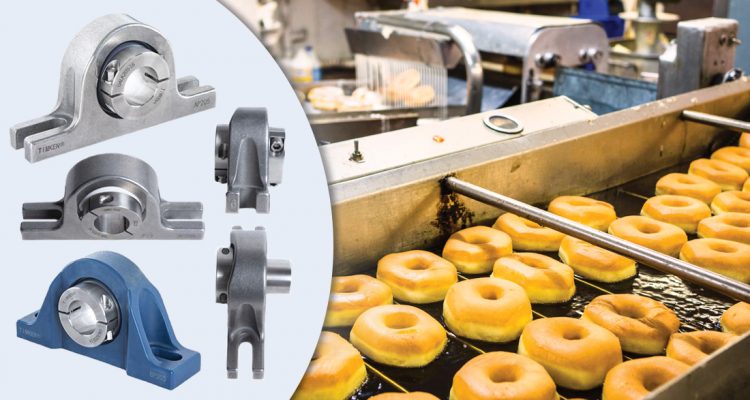

Brand new to the Australian market, and now serving exclusively at BSC: Timken food-grade bearings that can take the heat in the kitchen. “The food processing sector is a wealth of bearing solutions opportunities, particularly on high-heat conveying applications like industrial ovens and fryers,” says bearings expert Tony Tormey. “Timken is now offering bearing products suitable for fryers, cookers, freezers, process conveyors, oven roller applications, deep frying, and other pre‑cooking processes.”

Tony, BSC’s Product Manager for Industrial Bearings, says that bearings engineering has been rapidly evolving in the past few years to accommodate the specific needs of the food processing sector, which may have been overlooked in the past.

“Food products being precooked prior to packaging have a unique set of requirements,” says Tony. “Oven and fryer bearings need to be FDA-compliant, NSF H1 food-grade and approved by the United States Department of Agriculture (USDA), to align with current international food safety regulations.”

In addition to scorching temperatures, oven and fryer bearings are routinely exposed to cooking ingredients, steam, and moisture that could cause corrosion, so they need to be constructed from material that can withstand very high heat and ingress of contaminants.

“When manufacturing ovens and fryers, one of the biggest challenges is finding bearings that are suited to direct food contact and submergence in high temperature oils,” says Tony. “Careful consideration must be taken in the design and development of these bearing products. There can be no risks of cross-contamination or improper usage of chemicals on these applications. The integrity of the food products being processed cannot be compromised at the expense of consumer safety.”

Enter Alf Mangano — Timken’s Regional Sales Manager for the Victoria, Northern Territory and South Australian regions who has been specialising in bearings for the food and beverage industry for more than 23 years. He also looks after original equipment manufacturers (OEMs) for his sector of the bearings market. “It’s an exciting time for both Timken and BSC,” says Alf. “We have partnered with BSC on the promotion and distribution of our Oven and Fryer Bearings package, and we have given them exclusivity on the products.” “We have introduced several key products to the market: the Timken FA and FE Poly-Round® Housed Units, our premium bearing solution for fryer applications, and Timken QF Poly-Round bearings, designed specifically for oven applications,” he says. “It is our hope that in designing stronger bearing solution products that we can assist in streamlining food processing operations.”

“We are looking for businesses that have fryer and oven applications and bearings that have been underperforming on the job,” says Alf. “The idea will be to offer an upgrade to current bearing solutions. Timken’s fryer and oven bearing housings are designed to be dimensionally interchangeable, so if a customer has a bearing on an application that is not food grade, they can switch them out with ease. The Timken Poly-Round® have also been designed to be corrosion-resistant with lubricity in their polymer composition, which means they don’t require any further lubrication after install, according to Alf.

“The Poly-Round® bearings excel in the harsh conditions, extreme temperatures, abrasives, incomplete rotations – all while meeting food safety requirements,” says Alf. “And the built-in lubrication eliminates the need for grease and additional seals.”

“High-heat and hygiene are an engineering challenge in the bearings business, and as a result, we placed a lot of stock in washdown considerations,” he explains. “We understand that these applications will be making direct contact with food debris and undergoing rigorous regular sanitising processes.”

BSC is happy to be teaming up with Timken to roll out the new food-grade bearings solutions to the Australian market, even if it has been a slow burn to launch. “BSC and Timken share a joint cause in the desire to ease the pressures on our food processing customers,” says Tony. “Combined with a shared deep knowledge of the bearings business — this is a recipe for excellence,” he concludes.