When a local food manufacturer was experiencing issues with the longevity of the conveyor V-belts that convey their cereal products around sharp bends, CBC’s John Perri performed a joint call with a Gates® engineer to the customer’s site to discuss possible solutions.

“The most common issues I encounter with V-belts is in the tensioning and alignment,” says John. “Often times the belts are not fitted correctly on implementation, which causes them to jump, twist, and eventually fail. This means the customer ends up expending a lot of energy replacing them, so it’s very important we fit the correct belt with the right tensioning.”

Getting the heart of the issue on these kinds of applications is second nature to John. He’s been part of Motion Australia’s group of businesses for more than 22 years and serves as the Key Account Manager for New South Wales. He maintains close relationships with his clients in various sectors, getting out to site whenever possible, to keep tabs on how their equipment is operating and offer expert advice.

The customer contends with some of the highest demands in the food production sector, accounting for nearly a third of the value of gross domestic product in Australia. Furthermore, in recent years the industry has seen record breaking production from the ground up. In fact, the grain industry recorded one of the highest harvest yields on record in the 2020/2021 seasons, according to the Australian Government’s Grain Research and Development Corporation.1

The demands of the industry make it highly competitive in nature and mean food production facilities are always in need of better, faster, solutions for conveying product. In the case of his grain customer, John needed to find the most optimal belting solution—as quickly as possible.

“On this particular application, the conveyor was carrying the product around 90-degree bends,” says John. “Unfortunately for the customer, the belts were failing prematurely as the belts being used are not designed to bend in different directions experiencing frequent breakdowns and requiring long lead times for replacements which was slowing down production significantly.”

“A Gates® Engineer and I took a look at the customer’s service history and the OEM manual for the original factory belt selection for their conveyor system and found that it was manufactured outside of Australia,” he explains. “Based on the dimensions and application requirements, we looked at a couple of different solutions.”

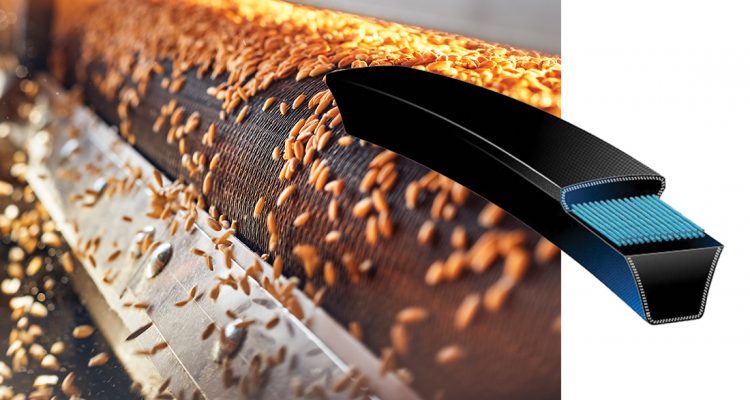

Originally, they looked at Gates® Round Endless Belts which are ideal for line shaft conveyors that have twisted or serpentine drives, but then they found that Gates® have a Power Curve™ V-belt range that covered the complete list of belts from their user manual better matched the specific sizing and was similarly, well-suited to the factory’s conveyor system.

“The Power Curve™ belt would allow for the belt to move on both planes without fatiguing,” notes John. “The belt would be able to withstand high speed movement in a forward direction and then abruptly sideways on a sharp angle.”

John arranged for the original belt to be replaced with the Gates® Power Curve™ V-belt for a trial and the customer was happy with this solution.

“In this instance, I think one of the main advantages we offered as a solutions provider was the ability to perform a joint site call with Gates®, who are one of our key suppliers,” says John. “They are one of our premium partners and we have enjoyed a working relationship that spans decades and has achieved positive results for all parties.”

Gates® Power Curve™ V-Belt

Features and Benefits:

• Ideal for conveyor turn on demanding applications

• Can contend with varying degrees of transverse bending

• Flex-Weave™ Cover constructed for longer cover life

• Superior protection of the belt core from oil, dirt, and heat

• Unique under cord construction allows greater than four times the flexibility of Gates standard B section belts

Reference:

- Australian Government, Grain Research and Development Corporation, Annual Report 2020-21. https://grdc.com.au/about/our-industry