Drive shafts are crucial components of machinery in the waste management and recycling industries, keeping equipment running and functioning effectively. Martin Hellings, the Technical Support Specialist at Hardy Spicer, specialist in industrial drive shafts, shared a recent success story where he and his Product Manager – Off Highway & Industrial Driveline, Russell Plowman helped a Laverton-based recycling company who required an important shredder machine upgrade.

“The company had purchased a new shredder machine with the capacity to run up to 8000hp 25% more than their existing shredder. However, an upgrade to the drive shaft applications in the machine was required,” Martin shared.

The drive shaft is extremely important in shredder machines, responsible for transmitting power from the motor to the shredder blades. Typically made of high-strength steel, it must be designed to withstand the high torque and bending forces generated by the shredder blades.

“Upgrading these components has two significant benefits. First, it improves the bearing life of the drive shafts, ensuring a longer period between replacements,” Martin explained.

“Furthermore, upgrading the drive shafts increases their functional limits, allowing the upgraded machine to handle greater loads and operate with improved efficiency,” Martin continued.

Martin says, with the ability to handle greater loads, the company can increase its production capacity and handle larger workloads without the need for additional equipment. This means that the company can scale up its operations and meet the growing demands of its customers, resulting in increased revenue and profits.

Moreover, by improving the machine’s efficiency, the company can reduce energy consumption, which can result in cost savings over time. In addition, improved efficiency can lead to less wear and tear on the machine, resulting in lower maintenance costs and longer equipment lifespans. This, in turn, can lead to better return on investment and lower total cost of ownership.

Martin worked closely with the business’s engineering department to identify the best drive shaft for the upgraded machine. Once the upgrade was completed, Martin continued to work with the business to ensure that the drive shaft was maintained correctly, maximising the lifespan of their equipment, and allowing the customer to continue enjoying the benefits of the upgrade.

This is an example of preventive maintenance, which involves taking proactive measures to ensure that equipment and machinery are regularly maintained and serviced to prevent issues before they occur. This will help prevent any unexpected breakdowns or malfunctions that could lead to downtime and lost productivity. By conducting regular maintenance and servicing, the business can ensure that their machinery continues to operate efficiently and effectively, ultimately resulting in cost savings and improved performance.

Downtime could have also negatively impacted the company’s ability to meet their production targets, potentially leading to missed deadlines and customer dissatisfaction.

Therefore, reducing likelihood of these events occurring through upgrades or regular maintenance is crucial in maximising the longevity and efficiency of machinery in the waste management and recycling industries.

He continued, “The customer was very happy with the outcome and bought a spare shaft as well,” showing they were extremely satisfied with the service they received.

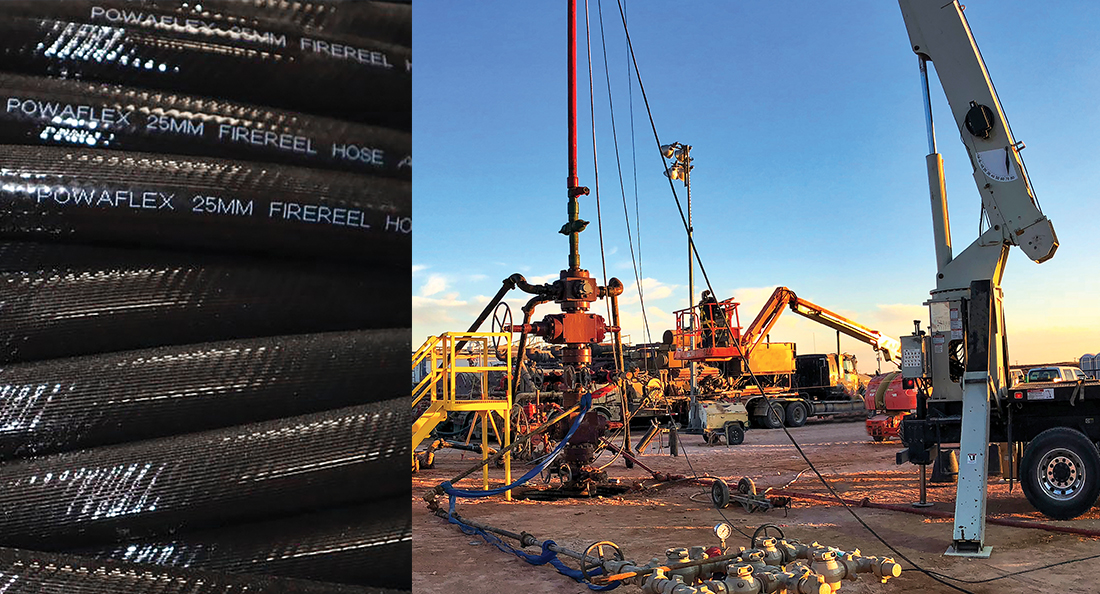

Hardy Spicer specialises in providing high-quality hydraulic and industrial hose and fittings, driveshafts, and universal joints to the Australian market. With over 70 years of experience in the industry, their products and services are specifically designed to perform in the toughest environments, such as mining and heavy industrial settings.

The work carried out by Martin Hellings and his team at Hardy Spicer is an example of the company’s commitment to providing customised solutions to its clients. With successful collaboration providing a tailored drive shaft solution, they completely boosted the machine’s performance, resulting in increased productivity and efficiency.

“It’s the service we offer from a Motion point of view. We can service the customer in so many ways, and Hardy Spicer fits into one of those baskets very successfully,” Martin describes.

This is just one of many success stories from the Motion-owned organisation Hardy Spicer, and this successful partnership greatly benefits their customers in the waste management and recycling as well as various other industries. If you’re interested in increasing your company’s production capacity, get in contact with a Motion expert today.