Did you know that an electric motor’s purchase price represents only 2% of its total cost of ownership?

According to the International Energy Agency, 69% of the energy used by industrial applications is related to electric motors, which are the driving force behind conveyor processes, pumps, heating and ventilation systems, and air compressors.

The annual energy cost of running motors on a mining operation far exceeds their initial purchase price. For example: At a rate of 15 cents per kilowatt-hour, a typical 15kW continuous running motor uses almost $21,000 worth of electricity annually – about 18 times its initial purchase price.

Replacing old standard efficiency 15kW motors can dramatically reduce your annual energy cost

“Replacing existing standard motors will immediately reduce a mine site’s annual electricity cost and delivering return on investment in less than 1.5 years,” according to Steve Hittmann, Motion Australia’s National Category Manager for Mechanical Drive Systems -Electric Motors. “In fact, the older the motor and the larger the motor’s kW per hour– the quicker the returns.”

“Motors are often mismatched—or oversized—for the load they are intended to serve,” says Steve. “Therefore, determining if motors are properly loaded enables operators to make informed decisions about when to replace motors and which replacements to choose.”

To compare the operating costs of an existing standard motor with an appropriately sized energy efficient replacement, Steve recommends that, with the help of motor efficiency experts like Motion Australia, mine site operators calculate operating hours, efficiency improvement values, and load.

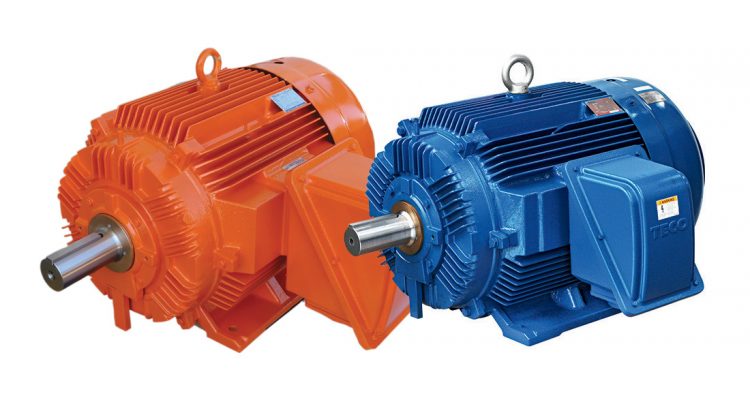

As a key supplier of electric motors to major mine sites in Australia, Motion works closely with motor manufacturers, such as TECO, to work out the cost‑benefits of adopting high-efficiency motors in mines.

Designed to withstand the heavy operating conditions of the mining industry, the TECO MAXe3 Mining and TECO MAXe3 Premium Severe Duty motors, offer an output range of 0.18 to 450kW, suitable for a wide range of applications.

The TECO MAXe3 high efficiency motors comply with IE3 efficiency level of IEC60034-30-1 standard and are designed to exceed the high efficiency requirements from Greenhouse and Energy Minimum Standards (GEMS) acts and regulations.

Not only do the motors exceed appropriate high efficiency standards, but they also offer superior power factor by minimising transmission losses in the supply cables and transformers and can operate safely in ambient temperatures of -20°C to 60°C in mining environments.

“At Motion Australia we want to help mine sites reduce their total cost of ownership by replacing standard motors with high‑efficiency motor solutions,” concludes Steve. “And TECO’s MAXe3 range offer the best efficiency available to the Australian market.”

To speak to a Motion Australia representative about replacing existing standard motors with high-efficiency alternatives, contact your local branch today.

TECO Maxe3 Premium Severe Duty Key Features

- Precision and rugged cast iron construction including fan

- Class F insulation system

- 1.5 service factor at 40°C ambient

- Suitable for 55°C ambient at rated output

- True IP66 with porous drain plugs

- TECO renowned grease relief system

- Thermistors for frames D160 and larger

TECO MaXe3 Mining Key Features

- Precision and rugged cast iron construction including fan

- Class H insulation system

- Superior inverter- rated insulation (8500V/microsecond)

- 1.2 service factor at 40°C ambient

- Suitable for 60°C ambient at rated output

- True IP66 with porous drain plugs

- TECO renowned grease relief system

- Two sets of thermistors for frames D160 and larger