Eliminating the risk of fire hazards and combustion is critical to keeping quarrying environments safe. For this reason, where the frequent use of explosives and harsh chemicals takes place, it is important that large pieces of machinery are adequately safeguarded against static charge.

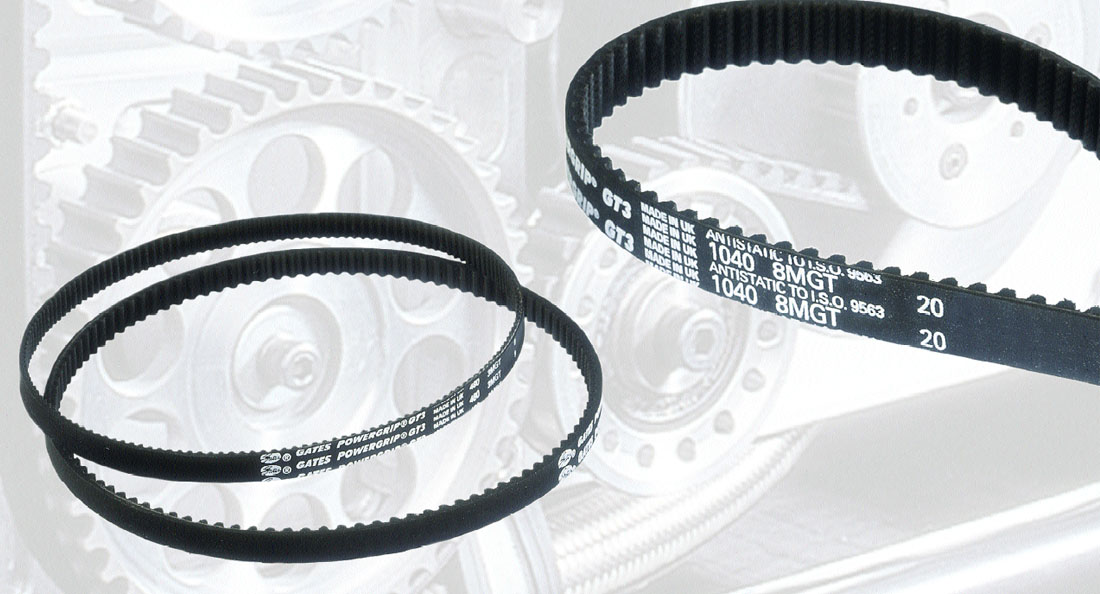

In 2020, Gates® introduced the PowerGrip® GT®4 high-torque synchronous belt to the Australian and New Zealand market. Constructed from rust-resistant ethylene elastomer (EE), this narrow, high-capacity drive belt is meticulously engineered to address durability, efficiency, noise reduction, and streamlined installation.

Importantly, it minimises the amount of friction and the build-up of heat caused by repetitive shock loads. Constructed in alignment with the ISO 9563 testing methods, this belt falls within the specified electrical resistance properties needed to safely operate in an explosive or fire-prone environment. Essentially, it is sufficiently conductive to dissipate electric charge that may form as the drive unit runs.

“One of the biggest challenges that quarries face is making sure that all stages of operation are compliant for the safety and wellbeing of personnel,” points out Michael Greelish, National Business Development Manager at Motion Australia.

“A straightforward way of doing this is opting for machinery and parts that are up to code, and designed with the industry-specific risks in mind.”

The PowerGrip GT4 is ideal for most types of heavy-duty quarrying equipment, such as driving pumps, fans, conveyor systems, drills and earth moving machinery. After just a couple of years in the field, the product has already set a new industry benchmark for its impressive power ratings. This is largely due to the company’s extensive research and development efforts, combining decades of technical knowledge with the latest in power transmission science.

Compared to the previous GT®3 series, this newer synchronous belt has boasted superior performance in all operating conditions. To combat a lack of consistent manufacturer standards for developing power rating tables, Gates has undergone a thorough rating development plan to ensure accurate modelling results.

Available in 8MGT and 14MGT pitches, the PowerGrip® GT®4 is a narrower band, without compromising on transmission capacity. This allows for more compact drive assemblies, and mitigates fatigue or strain during installation and change-outs.

In contrast to many other elastomer synchronous belts currently on the market, they are not fabricated from chloroprene, which harbours performance limitations and can have a negative impact on the environment. Instead, Gates® has pioneered an ethylene elastomer technology, which offers increased resistance to oxidation, heat, extreme weather, brake fluids, oil and grease. Paired with the internal fibreglass tensile cords and patented tooth profile, Michael says they are the next generation for optimum quarrying capacity.

“A fantastic feature to consider is that they require no lubrication or re-tensioning, which reduces huge amounts of downtime and maintenance costs,” he enthuses. “At Motion Australia, we stock a broad catalogue of Gates® products including compatible sprockets and pulleys, and our power transmission experts are available to carry out site inspections to audit individual customer requirements.”

Maddie the Miner recommends the PowerGrip® GT®4 for its:

• High tooth jump resistance

• Reduced environmental impact

• Improved safety and ergonomics

• Lubrication-free capabilities

• Chemical resistance

• Wide temperature range of -40°C to 120°C

• No stretching

• Various available widths of 20, 30, 50, 85mm (8MGT) or 40, 55, 85, 115, 170mm (14MGT)